RED LION CONTROLS CUB4V000

Datasheet

Extracted Text

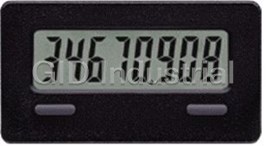

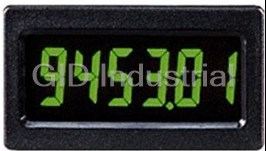

Bulletin No. CUB4V/I-J Drawing No. LP0256 Released 10/06 Tel +1 (717) 767-6511 Fax +1 (717) 764-0839 www.redlion.net MODEL CUB4I - MINIATURE D.C. CURRENT METER & MODEL CUB4V - MINIATURE D.C. VOLTMETER z LCD, POSITIVE REFLECTIVE OR NEGATIVE TRANSMISSIVE WITH YELLOW/GREEN OR RED BACKLIGHTING z FOUR SELECTABLE D.C. RANGES 0 to 199.9 mV, 1.999 V, 19.99 V, 199.9 V (CUB4V) 0 to 199.9 µA, 1.999 mA, 19.99 mA, 199.9 mA (CUB4I) z 0.6 INCH (15.2 mm) HIGH LCD DIGITS z BUILT-IN SCALING PROVIDED z AUTO ZEROING CIRCUIT z SELECTABLE DECIMAL POINTS z WIRE CONNECTIONS MADE VIA SCREW CLAMP TYPE TERMINALS z FITS DIN STANDARD CUT-OUT 2.68" (68 mm) x 1.30" (33 mm) z NEMA 4X/IP65 SEALED FRONT PANEL BEZEL UL Recognized Component, z 9 TO 28 VDC POWERED File # E179259 DESCRIPTION SPECIFICATIONS The CUB4 Volt and Current Meters are designed and manufactured using the 1. DISPLAY: 3½-digit (-1999 to 1999), 0.6" (15.2 mm) high digits. Minus (-) latest technology for a high quality, compact, affordable instrument for use in sign is displayed when voltage or current is negative. industrial environments. Each unit has a 3½-digit LCD display with 0.6 inch 2. DECIMAL POINTS: DIP switch selectable decimal points allow the display (15.2 mm) high digits and a DIP switch selectable decimal point. The displays to be read in tenths, hundredths or thousandths. are available in positive image reflective (black digits, reflective background) or 3. POWER REQUIREMENTS: negative image transmissive (illuminated digits, dark background) with red or Reflective Versions: 9 to 28 VDC at 4 mA max. yellow/green backlighting. Backlight Versions: 9 to 28 VDC @ 35 mA typ., 50 mA max. Above 26 The units are constructed of a lightweight, high impact plastic case with a VDC, derate operating temperature to 50°C. clear viewing window. The sealed front panel meets NEMA 4X/IP65 4. INPUT RANGES: D.C. VOLTAGE D.C. CURRENT specifications for wash-down and/or dusty environments, when properly (DIP Switch Selectable) (JMPR. Selectable) installed. A CUB4V or CUB4I unit can be mounted in the same panel cutout as ±199.9 mVDC ±199.9 µADC the CUBVD and CUBID units. ±1.999 VDC ±1.999 mADC The optional Micro Line/Sensor Power Supply (MLPS1000) is designed to ±19.99 VDC ±19.99 mADC ±199.9 VDC ±199.9 mADC attach to the rear of an installed CUB4V or CUB4I to provide the necessary power 5. ACCURACY: (@ 23°C, less than 85% RH) for the unit. The optional supply can be powered from a 85-250 VAC source. D.C. Voltage: ±(0.1% + 1 digit) D.C. Current: SAFETY SUMMARY 199.9 µA, 1.999 mA, 19.99 mA ranges: ±(0.1% + 1 digit) All safety related regulations, local codes and instructions that appear in the 199.9 mA range: ±(0.15% + 1 digit) manual or on equipment must be observed to ensure personal safety and to 6. OVERRANGE RATINGS, PROTECTION & INDICATION: prevent damage to either the instrument or equipment connected to it. If 9 to 28 VDC power circuit is not isolated from the signal circuit. equipment is used in a manner not specified by the manufacturer, the protection Max Input Voltage: provided by the equipment may be impaired. 0 to 199.9 mVDC Range: 75 VDC All other voltage Ranges: 300 VDC Max Input Current: 199.9 µA through 19.99 mA: 10 times max. range current 199.9 mA: 1 amp Overrange Indication: Overrange is indicated by a “1” displayed in the CAUTION: Read complete CAUTION: Risk of electric shock. most significant digit and the blanking of the three least significant digits. instructions prior to installation 7. READING RATE: 2.5 readings per second and operation of the unit. 8. RESPONSE TIME: 1.5 seconds to settle for a step change 9. NORMAL MODE REJECTION: 60 dB 50/60 Hz Note: Recommended minimum clearance (behind the panel) for mounting clip DIMENSIONS In inches (mm) installation is 2.15" (54.6) H x 3.00" (76.2) W. 1 10. INPUT IMPEDANCE: Notes: Voltmeter: 1 MΩ 1. Self-recoverable loss of performance during EMI disturbance at 10 V/m. Current Meter: Process signal may deviate during EMI disturbance. 199.9 µA - 1 KΩ For operation without loss of performance: 1.999 mA - 100 Ω Unit is mounted in a metal enclosure (Buckeye SM7013-0 or equivalent) 19.99 mA - 10 Ω I/O and power cables are routed in metal conduit connected to earth 199.9 mA - 1 Ω ground. 11. CERTIFICATIONS AND COMPLIANCES: 2. Self-recoverable loss of performance during EMI disturbance at 10 Vrms. SAFETY Process signal may deviate during EMI disturbance. UL Recognized Component, File # E179259, UL3101-1, CSA C22.2 No. 1010-1 For operation without loss of performance: Recognized to U.S. and Canadian requirements under the Component Install power line filter RLC#LFIL0000 or equivalent at the unit. Recognition Program of Underwriters Laboratories, Inc. Refer to the EMC Installation Guidelines section of this bulletin for Type 4X Enclosure rating (Face only), UL50 additional information. IECEE CB Scheme Test Certificate # UL2356A-179259/USA, 12. ENVIRONMENTAL CONDITIONS: CB Scheme Test Report # 98ME60090-000098 Operating Temperature: 0° to 60°C (above 50°C, derate backlight Issued by Underwriters Laboratories, Inc. operating voltage to 26 VDC maximum). IEC 1010-1, EN 61010-1: Safety requirements for electrical equipment Storage Temperature: -40° to 80°C for measurement, control, and laboratory use, Part 1. Operating and Storage Humidity: 85% max relative humidity (non- IP65 Enclosure rating (Face only), IEC 529 condensing) from 0 to 60°C. ELECTROMAGNETIC COMPATIBILITY Vibration According to IEC 68-2-6: 5 to 500 Hz, in X, Y, Z direction for 1.5 hours, 5g’s. Immunity to EN 50082-2 Shock According to IEC 68-2-27: Operational 30 g, 11 msec in 3 directions. Electrostatic discharge EN 61000-4-2 Level 2; 4 Kv contact Temperature Coefficient: 100 PPM/°C Level 3; 8 Kv air 1 Altitude: Up to 2000 meters. Electromagnetic RF fields EN 61000-4-3 Level 3; 10 V/m 13. CONSTRUCTION: High impact plastic case with clear viewing window. 80 MHz - 1 GHz (Panel gasket and mounting clip included.) This unit is rated for NEMA Fast transients (burst) EN 61000-4-4 Level 4; 2 Kv I/O 4X/IP65 indoor use. Installation Category II, Pollution Degree 2 Level 3; 2 Kv power 14. WEIGHT: 3.3 oz. (93.5 g) 2 RF conducted interference EN 61000-4-6 Level 3; 10 V/rms 150 KHz - 80 MHz Power frequency magnetic fields EN 61000-4-8 Level 4; 30 A/m Simulation of cordless telephone ENV 50204 Level 3; 10 V/m 900 MHz ± 5 MHz 200 Hz, 50% duty cycle Emissions to EN 50081-2 RF interference EN 55011 Enclosure class A Power mains class A INSTALLATION ENVIRONMENT The unit should be installed in a location that does not exceed the maximum operating temperature and provides good air circulation. Placing the unit near devices that generate excessive heat should be avoided. The bezel should be cleaned only with a soft cloth and neutral soap product. Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the aging process of the bezel. Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the keypad of the unit. Installation The CUB4 Volt and Current meters meet NEMA 4X/IP65 requirements for indoor use, when properly installed. The units are intended to be mounted into an enclosed panel. A sponge rubber gasket, mounting clip, two screws, and nut fasteners are provided to install and seal the unit in the panel cutout. The following procedure assures proper installation: 1.Cut panel opening to specified dimensions. Remove burrs and clean panel opening. 2. Carefully remove center section of the panel gasket and discard. Slide gasket over rear of the unit to the back of the bezel. 3. Slide nut fastener into slot on mounting clip and then insert mounting screw through nut on both sides of mounting clip. Tip of mounting screw should NOT project through hole on clip. 4. Install CUB4 unit through panel cutout. 5. Slide mounting clip over rear of unit until clip is against back of panel. The mounting clip and CUB4 housing have a latching feature to hold the unit in place until tightened. Note: Hold the CUB4 front bezel in place when sliding the mounting clip into position. 6. Alternately tighten each mounting screw to ensure uniform gasket pressure. 7. If the gasket is not adequately compressed and the mounting screws cannot Visually inspect the gasket for proper seal. The gasket should be be tightened any further, loosen mounting screws and insure that the clip is compressed approximately 75 to 80% of its original thickness. latched as close as possible to the panel. (Recommended torque is 28 to 36 in-oz.) 8. Repeat step #6 for tightening the mounting screws. 2 EMC Installation Guidelines CUB4V SIGNAL INPUT Although this unit is designed with a high degree of immunity to The voltage range is selected by setting one of the DIP switches S1 to S4 ElectroMagnetic Interference (EMI), proper installation and wiring methods for the desired input voltage. The unit will indicate the direct readout for the must be followed to ensure compatibility in each application. The type of range selected. electrical noise, source or coupling method into the unit may be different for Note: Only one Voltage Range switch (S1-S4) should be selected (ON). various installations. Cable length, routing and shield termination are very important and can mean the difference between a successful or a troublesome The SCALE DIP switch (S5) and the Scaling Potentiometer are used installation. Listed below are some EMC guidelines for successful installation when it is necessary to scale the display to indicate other engineering units. in an industrial environment. The Scale switch should be left in the “OFF” position when the application requires direct voltage readout on the display. 1. The unit should be mounted in a metal enclosure, which is properly The Calibration Potentiometer has been set at the factory and should not be connected to protective earth. adjusted unless the unit is being re-calibrated with an accurate voltage source. 2. Use shielded (screened) cables for all Signal and Control inputs. The shield The power supply common and signal common are connected internally (screen) pigtail connection should be made as short as possible. The at the same screw terminal marked COMM. The power supply common, connection point for the shield depends somewhat upon the application. and the signal common must be at the same voltage potential. The voltmeter Listed below are the recommended methods of connecting the shield, in cannot measure a voltage with a reference that is different than the power order of their effectiveness. supply common. a. Connect the shield only at the panel where the unit is mounted to earth ground (protective earth). b. Connect the shield to earth ground at both ends of the cable, usually when the noise source frequency is above 1 MHz. c. Connect the shield to common of the unit and leave the other end of the shield unconnected and insulated from earth ground. 3. Never run Signal or Control cables in the same conduit or raceway with AC power lines, conductors feeding motors, solenoids, SCR controls, and heaters, etc. The cables should be run in metal conduit that is properly grounded. This is especially useful in applications where cable runs are long and portable two-way radios are used in close proximity or if the installation is near a commercial radio transmitter. 4. Signal or Control cables within an enclosure should be routed as far away as possible from contactors, control relays, transformers, and other noisy components. 5. In extremely high EMI environments, the use of external EMI suppression devices, such as ferrite suppression cores, is effective. Install them on Signal and Control cables as close to the unit as possible. Loop the cable through the core several times or use multiple cores on each cable for additional protection. Caution: The Maximum Voltage for each switch position must not Install line filters on the power input cable to the unit to suppress power line be exceeded or the unit may be damaged (See Specifications). interference. Install them near the power entry point of the enclosure. The following EMI suppression devices (or equivalent) are recommended: Ferrite Suppression Cores for signal and control cables: Caution: 9 to 28 VDC power circuit is not isolated from the Fair-Rite # 0443167251 (RLC #FCOR0000) signal circuit. TDK # ZCAT3035-1330A Steward #28B2029-0A0 Line Filters for input power cables: Schaffner # FN610-1/07 (RLC #LFIL0000) Schaffner # FN670-1.8/07 Corcom #1VR3 Note: Reference manufacturer’s instructions when installing a line filter. 6. Long cable runs are more susceptible to EMI pickup than short cable runs. Therefore, keep cable runs as short as possible. WIRING CONNECTIONS The electrical connections are made via screw-clamp terminals located on the back of the unit. When wiring the unit, use the label to identify the wire position with the proper function. All conductors should meet voltage and current ratings for each terminal. Also cabling should conform to appropriate standards of good installation, local codes and regulations. It is recommended that power supplied to the unit be protected by a fuse or circuit breaker. Strip the wire, leaving approximately ¼" bare wire exposed (stranded wires should be tinned with solder). Insert the wire into the screw-clamp terminal and tighten the screw until the wire is clamped tightly. Each terminal can accept up to two #14 AWG wires. DECIMAL POINT SELECTION The CUB4 Volt and Current Meters can be set-up to read in 10ths, 100ths, or 1000ths. The decimal point position is DIP switch selectable for one of three locations. If all the DIP switches are set to the “OFF” position, then NO decimal point will appear in the display. The DIP switches are located at the rear of the unit. 3 VOLTMETER SCALING CUB4I SIGNAL INPUT In many industrial applications, a voltmeter is required to display a reading The CUB4 Current Meter has four current ranges that are selected by in terms of PSI, RPM, or some other unit of measure. The signal voltage being positioning the jumper in the proper location on the male header strip. measured is normally generated by a transducer which senses the variable and The SCALE DIP switch (S1) and the Scaling Potentiometer are used delivers a linear output voltage. To provide the desired readout at the specified when it is necessary to scale the display to indicate other engineering units. voltage, the voltmeter must be scaled. The Scale switch, when in the “ON” The Scale switch should be left in the “OFF” position when the application position, enables the Scale Potentiometer. The Scale Potentiometer is used with requires direct current readout on the display. a voltage range to provide a method of scaling the unit. The voltage DIP When the power supply is floating (unreferenced) to the desired switches are used to select one of the four coarse Division Factor ranges and the measurement points, the (-) signal input and the power supply common Scale Potentiometer is a fine scale adjustment within the selected range. The should be connected. If the power supply is not floating (referenced), the chart below shows the division factor range associated with each range common mode voltage between the (-) signal input and power supply selection switch. common terminal must not be greater than 1.0 V peak. A common mode DIVISION FACTOR RANGE SELECTION CHART voltage higher than 1.0 V peak will result in a measurement error. S1: 0-199.9 mVDC (0.1 D.F. 1.2) The Calibration Potentiometer has been set at the factory and should not be S2: 0-1.999 VDC (1.2 D.F. 10.5) adjusted unless the unit is being re-calibrated with an accurate current source. S3: 0-19.99 VDC (10.5 D.F. 100.5) S4: 0-199.9 VDC (100.5 D.F. 1300) Note: Enabling the Scale Potentiometer does NOT affect the calibration of the unit. To determine the proper voltage range for an application requiring scaling, the “Division Factor” required to provide the proper display reading must first be determined by using the following formula. USING THE FORMULA: VT x D.D.P. D.F = D.R. WHERE: VT = Maximum Transducer Output D.D.P. = Display Decimal Point D.F. = Division Factor D.R. = Desired Reading D.D.P. 0.000 = 1 The DISPLAY DECIMAL POINT (D.D.P.) 00.00 = 10 is determined by the desired decimal 000.0 = 100 point placement in the readout. 0000 = 1000 After the Division Factor for the application has been calculated, the proper voltage range switch that will provide for the Division Factor is set to the “ON” Caution: The Maximum Current for each jumper position must not position. Use the “Division Factor Range Selection Chart” to choose the proper be exceeded or the unit may be damaged (See Specifications). DIP switch setting. Note: Only one voltage DIP switch should be turned on. Set the switch before the voltage signal is applied. CURRENT METER SCALING The CUB4 Current Meter display can be scaled to almost any lower EXAMPLE: A relative humidity transducer delivers a 7.0 VDC voltage at a numerical value. Setting the Scale switch to the “ON” position enables the relative humidity of 75%. Scale Potentiometer, which is used with the current range selection jumper to VT x D.D.P. 7.0 x 1000 D.F. = = = 93.3 scale the unit. The Scale potentiometer can be set to divide the normal current D.R. 75 reading by a division factor between 1 and 13. This Division Factor is between 10.5 and 100.5, therefore DIP switch position S3 is set to the “ON” position. The Scaling Potentiometer is then EXAMPLE: The CUB4 Current Meter has been connected to measure a circuit current to 120.0 mA maximum. However, in this application, the display is to adjusted for the desired readout at a known relative humidity. indicate percent of load current with 120.0 mA equivalent to 100.0 percent. BLOCK DIAGRAM CUB4V The scale potentiometer is adjusted to reduce the normal 120.0 mA signal input display reading of 120.0 to indicate the desired reading of 100.0 on the display. Scaling to obtain a numerical readout higher than the normal value of the current can also be accomplished in most cases by selecting a lower current range. However, the maximum current for the range must not be exceeded. (See Specifications for maximum input currents.) BLOCK DIAGRAM CUB4I 4 TYPICAL VOLT & CURRENT MEASUREMENT APPLICATIONS VOLTMETER APPLICATION CURRENT METER APPLICATION Indicating the Speed of a D.C. Motor Analog Meter Replacement A foreman in a plant wants to get a more accurate indication of the speed A manufacturer wants to replace several 1 mA DC analog meter at which a variable speed DC motor drive is operating. The only indication movements with easy to read CUB4 Current Meters with backlighting. One he has now is the position of a dial on the control panel. application involves measuring the flow rate of a liquid to indicate 0 to 250 The motor has a tachometer generator that will output a 10 VDC signal gallons per minute. when the motor is running at its maximum speed of 1800 RPM. The power supply of the control has a 15 VDC output that can supply power to the CUB4V. Since this application requires a non-standard readout, it will be necessary to scale the display. The Scale DIP switch is set to the “ON” position to enable the Scale Potentiometer. The Division Factor is calculated using the formula: (Maximum output) x D.D.P. D.F. = (Desired Display) 10 x 1000 D.F. = 1800 D.F. = 5.5 Since 1 mA of current flow requires a display reading of 250, the CUB4 Current Meter will need to be scaled. The Scale DIP switch is set to the “ON” position enabling the Scale Potentiometer. The proper current range for the application is then selected. The Scale potentiometer will divide the display reading by 1 to 13, for the particular current range selected. A reading of 250 is 4 times less than the normal reading at 1 mA for the 0 to 1.999 mA range, therefore the jumper is installed in the 0-1.999 mA range position. No decimal point is selected because the resolution is 1 gallon. The CUB4 Current Meter can now be scaled. Apply 1 mA to the signal input and adjust the scale potentiometer to the desired reading. Since the division factor falls between 1.2 and 10.5, DIP switch position S2 is set to the “ON” position, according to the Division Factor Selection Chart. To scale the CUB4 Voltmeter, the motor is run at full speed and a calibrated photo tachometer is used to obtain the exact speed. The Scale Potentiometer on the CUB4 Voltmeter is then adjusted until the display reading agrees with the tachometer. Alternately, the output of a precision voltage source set to +10 VDC can be connected to the signal input of the TROUBLESHOOTING unit and then adjust the scaling potentiometer for the desired reading. For further technical assistance, contact technical support at the appropriate company numbers listed. ORDERING INFORMATION MODEL NO. DESCRIPTION PART NUMBERS DC Voltmeter CUB4V000 CUB4V DC Voltmeter W/Yel-Grn Backlighting CUB4V010 DC Voltmeter W/Red Backlighting CUB4V020 DC Current Meter CUB4I000 CUB4I DC Current Meter W/Yel-Grn Backlighting CUB4I010 DC Current Meter W/Red Backlighting CUB4I020 MLPS Micro Line/Sensor Power Supply MLPS1000 5 This page intentionally left blank 6 This page intentionally left blank 7 LIMITED WARRANTY The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to two years from the date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The Company’s liability under this limited warranty shall extend only to the repair or replacement of a defective product, at The Company’s option. The Company disclaims all liability for any affirmation, promise or representation with respect to the products. The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses arising out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal injuries, deaths, property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to any extent liable, including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter. No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein. The Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations. Red Lion Controls AP Red Lion Controls Red Lion Controls BV 31, Kaki Bukit Road 3, 20 Willow Springs Circle Basicweg 11b #06-04/05 TechLink York PA 17402 NL - 3821 BR Amersfoort Singapore 417818 Tel +1 (717) 767-6511 Tel +31 (0) 334 723 225 Tel +65 6744-6613 Fax +1 (717) 764-0839 Fax +31 (0) 334 893 793 Fax +65 6743-3360

Frequently asked questions

What makes Elite.Parts unique?

What kind of warranty will the CUB4V000 have?

Which carriers does Elite.Parts work with?

Will Elite.Parts sell to me even though I live outside the USA?

I have a preferred payment method. Will Elite.Parts accept it?

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods