RADISYS EPC-2101

Specifications

Chipset

Intel 430HX PCIset

Processor

Intel Pentium processor:100/133/166 MHz, 64-bit Classic Pentium (P54C)166/200/233 MHz, 64-bit Pentium with MMX (P55C)

Features

- 100/133/166 MHz, 64-bit Classic Pentium (P54C)

- 166/200/233 MHz, 64-bit Pentium with MMX™ (P55C)

- 4 Mb (512 KB x 8) flash memory

- 8-pin AT keyboard/speaker/reset header

- 82371SB PCI I/O IDE Xcelerator (PIIX3, or South-Bridge)

- 82439HX System Controller (TXC, or North-Bridge)

- CHIPS 65550 High Performance Multimedia Flat Panel / CRT GUI Accelerator with flat

- Dallas DS2109 Plug and Play SCSI terminator (EPC-2100 only)

- DS1687 compatible Real-Time Clock module with embedded battery

- Floppy drive controller

- Four 256 KB x 16 on-board video DRAM modules (2 MB)

- Four SIMM sockets for up to 256 MB scaleable DRAM

- Intel 430HX PCIset

- Intel 82091AA Advanced Integrated Peripheral (AIP)

- Intel Pentium processor:

- Level 2 write-back cache socket for 256 or 512 KB pipeline burst COAST SRAM

- Note: The EPC-2100/EPC-2101 supports up to 256 MB FPM or up to 128 MB EDO.

- only)

- panel display header

- Parallel port (AT-compatible / bi-directional / EPP)

- PCI Adaptec AIC-7850 SCSI Host Adapter with Fast/Narrow SCSI-2 header (EPC-2100

- PCI EIDE hard disk drive controller

- PS/2 mouse and keyboard connectors

- Two serial ports (one RS-232 only; one RS-232 or RS-422)

- VGA video connector on the I/O bracket

Datasheet

Extracted Text

SERVICE MANUAL

®

EPC -2100/EPC-2101

PV5000HX2(-IDE) Series SBC

P/N 007-01246-0000 June 2001

© 2001 RadiSys Corporation

All Rights Reserved

Printed in USA

EPC-2100 and EPC-2101 Single-Board Computers

Limited Warranty

A. RadiSys Corporation warrants that the item sold by it hereunder will be free from defects

in materials or workmanship, under normal use and service, for a period of 2 years from

date of shipment. Said item will meet the specifications in effect at the time of

manufacture. The sole obligation of RadiSys under this warranty shall be, at its option, to

repair or replace, without charge, any defective component of said item, within a

reasonable period of time.

B. RadiSys Corporation shall not be liable under this warranty for (i) the item that the Buyer

alleges to be defective and was repaired or altered by someone other than an authorized

representative of RadiSys, unless such repair or alteration was effected pursuant to prior

written approval of RadiSys, or (ii) where the Buyer fails to notify RadiSys of any alleged

defect within the period of warranty, or (iii) where the Buyer fails to return the allegedly

defective item to RadiSys Corporation, in Houston, Texas, USA, freight prepaid, or (iv)

where the item was altered or damaged in a way which RadiSys reasonably determines to

affect the performance and reliability of the item, or (v) where the item was subject to

misuse, neglect, or accident. The rights and remedies granted to the Buyer under this

paragraph constitute the Buyer's sole and exclusive remedy against RadiSys Corporation,

its officers, agents, and employees, for negligence, inexcusable delay, breach of warranty,

express or implied, or any other default relating to the item or the duties of RadiSys to

eliminate any errors.

This warranty supersedes any other warranty, whether expressed, implied, or statutory,

including but not limited to any warranty for fitness of purpose, merchantability, or freedom

from infringement or the like, and any warranty otherwise arising out of any proposal,

specifications, or sample. Furthermore, RadiSys Corporation neither assumes nor authorizes

any person to assume for it any other liability.

The software included with this equipment is warranted only in accordance with the terms of

its license agreement. Except as warranted in that license agreement, the manufacturer of the

software disclaims all warranties and conditions with regard to the software, including all

implied warranties and conditions of merchantability, fitness for a particular purpose, title, and

non-infringement.

Every effort has been made to ensure that the information provided in this manual is complete

and accurate. However, technical inaccuracies or typographical errors may be inadvertently

included. RadiSys assumes no responsibility for any errors that may be contained in this

document. RadiSys makes no promise to update or keep current the information contained in

this document. Information in this document, including product specifications, is subject to

change without notice.

All tradenames referenced are the service mark, trademark, or registered trademark of the

respective manufacturer.

ii Service Manual

Important

Always use caution when handling or operating the equipment. Only qualified and trained

electronics service personnel should access the equipment. Use extreme caution when

installing or removing components. For additional information, please contact RadiSys

Technical Support at 800–627–8700 or 713–541–8200 Monday through Friday between

8:00 a.m. and 5:00 p.m., Central Time, continental USA.

Wichtig

Arbeiten am System bzw. Betrieb des Systems, sollten immer mit der nötigen Vorsicht

vorgenommen werden. Nur qualifiziertes und ausgebildetes Fachpersonal sollte am Inneren

des Gerätes arbeiten. Beim Installieren und Entfernen von Komponenten ist besondere

Vorsicht geboten.

Für weitere Informationen wenden Sie sich bitte an den Technical Support von RadiSys:

• USA: 800–627–8700 oder 713–541–8200 Montags bis Freitags von

0800 Uhr bis 1700 Uhr, Central USA.

International: +31–36–5365595 Montags bis Freitags von 0830 Uhr bis 1700 Uhr.

(CET GMT +1.00)

Changes or modifications not expressly approved by RadiSys Corporation could void the

product warranty and the user’s authority to operate the equipment.

Service Manual iii

EPC-2100 and EPC-2101 Single-Board Computers

Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can emit radio frequency energy and, if not installed and

used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case, the user will be required to correct the interference at the user’s

expense.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions:

This device may not cause harmful interference

This device must accept any interference received, including interference that may cause

undesired operation

Any change or modification not expressly approved by the manufacturer is prohibited and

could void the user’s authority to operate the equipment.

This product also meets requirements for compliance with EN55022, Class B ITE.

iv Service Manual

Symbols

Notice:

This symbol indicates an item for special consideration.

Warning:

This symbol indicates the presence of a potential hazard that can

cause personal injury or equipment damage. Only qualified and

trained electronics service personnel should access the equipment.

Service Manual v

EPC-2100 and EPC-2101 Single-Board Computers

Customer Support

Accessing the Web Site

In-depth printable service manuals and other documentation are available for download from

the RadiSys Web site:

http://www.radisys.com

Then click on Support to access a link to the documentation, drivers, and BIOS.

® ®

Documentation is available at this Web site in Adobe Acrobat .PDF format, and may be

® ™

viewed and printed using the free Acrobat Reader software. BIOS files are available as self-

extracting disk image files. Links are provided to various partners’ web sites where any files

and tools needed to install drivers are available for download.

Calling Technical Support

1. Have the RadiSys product model and serial number available.

2. Call Technical Support:

In the continental USA, Monday – Friday, 8:00 a.m. – 5:00 p.m., Central Time, dial

800–627–8700.

Outside the USA, dial 713–541–8200 (add long distance/international access codes).

In Europe, Monday – Friday, 8:30 a.m. – 5:00 p.m., dial +31–36–5365595.

Inspection of Contents / Packaging of Product

The packaging for this product has been tested to assure that it will withstand responsible

handling by the carrier.

Caution: Inspect contents immediately and file a claim with the delivering carrier for any

damage. Save the shipping box and packaging material to use for any further shipment of this

equipment.

However, if the packaging is damaged and is not suitable for shipment, call RadiSys Technical

Support to obtain new packaging. The warranty may be void if the product is returned using

unapproved or damaged original packaging.

Returning Your Product

A Returned Material Authorization (RMA) number must be written on the outside of the

shipping carton of all equipment returned to RadiSys for service and/or repair. It is

recommended that any correspondence included with the carton contents also refer to the

RMA number.

Note: The factory will refuse the shipment if it is sent freight collect or if it does not display

an RMA number.

vi Service Manual

Table of Contents

Chapter 1 Introduction 1

EPC-2100/2101 (PV5000HX2(-M)) Series SBC...................................................................2

Chapter 2 7 Steps to Operation 5

Handling the EPC-2100/2101.................................................................................................6

Step 1: Check Jumper Settings ...............................................................................................8

Step 2: Check Switch Settings..............................................................................................10

Step 3: Install the SBC .........................................................................................................12

Step 4: Attach Peripherals to Headers ..................................................................................14

Step 5: Attach Peripherals to Connectors.............................................................................16

Step 6: Power-On the System...............................................................................................18

Step 7: Run the Setup Utility................................................................................................19

Chapter 3 Technical Data 27

Specifications .......................................................................................................................28

Pin Signals ............................................................................................................................30

Display System.....................................................................................................................36

Installing Memory ................................................................................................................38

Service Manual vii

EPC-2101 Single-Board Computer

List of Figures

Figure 1. Components and Layout..................................................................................... 3

Figure 2. Safely Handling the SBC ................................................................................... 7

Figure 3. Jumper Block Locations..................................................................................... 9

Figure 4. Switch Block Location ..................................................................................... 11

Figure 5. Installing the SBC ............................................................................................ 13

Figure 6. Peripheral Header Locations ............................................................................ 15

Figure 7. Peripheral Connector Locations ....................................................................... 17

Figure 8. Setup Utility Main Menu.................................................................................. 20

Figure 9. Serial and Parallel Headers and Connectors..................................................... 31

Figure 10. Peripheral Headers and Connectors ................................................................. 33

Figure 11. Flat Panel Display Header................................................................................ 35

Figure 12. Memory Sockets............................................................................................... 39

viii Service Manual

List of Tables

Table 1. Jumper Block Settings ........................................................................................... 8

Table 2. Jumper Block Functions ........................................................................................ 9

Table 3. Switch Settings .................................................................................................... 10

Table 4. Installing the SBC................................................................................................ 12

Table 5. Main Menu Options and Item Values.................................................................. 21

Table 6. Advanced Menu Options and Item Values.......................................................... 22

Table 7. Security Menu Options and Item Values............................................................. 24

Table 8. Power Menu Options and Item Values ................................................................ 24

Table 9. Server Menu Options and Item Values................................................................ 25

Table 10. Environmental Tolerances ................................................................................... 28

Table 11. System Specifications .......................................................................................... 29

Table 12. Serial and Parallel Port Pin Signals ..................................................................... 30

Table 13. Peripheral Header and Connector Pin Signals..................................................... 32

Table 14. Flat Panel Display Header Pin Signals ................................................................ 34

Table 15. Memory Combinations ........................................................................................ 39

Service Manual ix

EPC-2101 Single-Board Computer

Notes

x Service Manual

Introduction Chapter 1

1

This chapter discusses the primary features of the EPC-2100/EPC-2101 Single-

Board Computer (PV5000HX2 series).

If you are familiar with the primary components and functions of the

EPC-2100/EPC-2101, and you wish to quickly begin operating the SBC, go to

Chapter 2, “7 Steps to Operation,” page 5. Then read this chapter later at your

convenience.

Service Manual 1

EPC-2100/EPC-2101 Single-Board Computer

EPC-2100/2101 (PV5000HX2(-M)) Series SBC

Overview

The RadiSys EPC-2100/EPC-2101 Single Board Computers (SBC) provide the following

features:

™ ®Intel Pentium processor:

100/133/166 MHz, 64-bit Classic Pentium (P54C)

™

166/200/233 MHz, 64-bit Pentium with MMX (P55C)

Intel 430HX PCIset

82439HX System Controller (TXC, or North-Bridge)

82371SB PCI I/O IDE Xcelerator (PIIX3, or South-Bridge)

Intel 82091AA Advanced Integrated Peripheral (AIP)

DS1687 compatible Real-Time Clock module with embedded battery

4 Mb (512 KB x 8) flash memory

Level 2 write-back cache socket for 256 or 512 KB pipeline burst COAST SRAM

Four SIMM sockets for up to 256 MB scaleable DRAM

Note: The EPC-2100/EPC-2101 supports up to 256 MB FPM or up to 128 MB EDO.

Two serial ports (one RS-232 only; one RS-232 or RS-422)

Parallel port (AT-compatible / bi-directional / EPP)

Floppy drive controller

PCI EIDE hard disk drive controller

PCI Adaptec AIC-7850 SCSI Host Adapter with Fast/Narrow SCSI-2 header (EPC-2100

only)

Dallas DS2109 Plug and Play SCSI terminator (EPC-2100 only)

CHIPS 65550 High Performance Multimedia Flat Panel / CRT GUI Accelerator with flat

panel display header

VGA video connector on the I/O bracket

Four 256 KB x 16 on-board video DRAM modules (2 MB)

PS/2 mouse and keyboard connectors

8-pin AT keyboard/speaker/reset header

Note: The EPC-2100 and EPC-2101 are members of the PV5000HX2 family of single-board

computers. The EPC-2100 supports SCSI and IDE; the EPC-2101 supports IDE only.

More...

For more information on the components of the EPC-2100/EPC-2101, contact:

Company Telephone Website

Intel Corporation (602) 554-8080 http://www.intel.com

Adaptec, Inc. (408) 945-8600 http://www.adaptec.com

Asiliant Technologies (formerly C&T) (408) 467-0755 http://www.asiliant.com

Dallas Semiconductor Corporation (972) 788-2197 http://www.dalsemi.com

PCI Special Interest Group (503) 696-2000 http://www.pcisig.com

PICMG (781) 246-9318 http://www.picmg.com

2 Service Manual

Chapter 1: Introduction

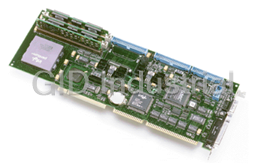

Figure 1. Components and Layout

2 34 56 7P 8

9

G

D

J

F

I

H

10

C

11

M

N

OOOO

A

E

K L

12

13

1

B

A. Intel Pentium P54C/P55C Processor 1. Keyboard Header

B. Pentium Processor with Heatsink 2. EIDE Drive Header

C. Level 2 SRAM Cache Socket 3. IDE/SCSI Activity LED Header

D. DRAM SIMM Sockets 4. SCSI Drive Header (EPC-2100 only)

E. Intel 82439HX System Controller (TXC, 5. Flat Panel Display Header

or North-Bridge)

6. Parallel Port Header

F. Intel 82371SB PCI I/O IDE Accelerator (PIIX3,

7. Floppy Drive Header

or South-Bridge)

8. Serial Port 2 Header

G. Dallas DS2109 PnP SCSI Terminator (EPC-2100 only)

9. I/O Bracket

H. Adaptec AIC-7850 SCSI Host Adapter (EPC-2100 only)

10. VGA Video Connector

I. Dallas DS1687 compatible Real-Time Clock

11. PS/2 Mouse Connector

J. Intel 82091AA Advanced Integrated Peripheral (AIP)

12. Serial Port 1 Connector

K. Speaker

13. PS/2 Keyboard Connector

L. Flash Device

M. Auxiliary BIOS

N. CHIPS 65550 Flat Panel / CRT Accelerator

O. Video DRAM modules

P. DIP Switch Block

Service Manual 3

EPC-2100/EPC-2101 Single-Board Computer

Notes

4 Service Manual

7 Steps to Operation Chapter 2

2

This chapter describes basic precautions for handling the EPC-2100/2101, and

then outlines the basic steps for setting up the SBC:

1. Check jumper settings

2. Check switch settings

3. Install the SBC

4. Attach peripheral devices to headers

5. Attach peripheral devices to connectors

6. Power-on the system

7. Run the Setup Utility

Service Manual 5

EPC-2100/2101 Single-Board Computer

Handling the EPC-2100/2101

Overview

This section suggests basic precautions when handling the EPC-2100/2101 series SBC.

Static Electricity

The EPC-2100/2101 series is designed to protect against ESD (electro-static discharge) and

excessive voltage. However, excessive static electricity can damage components.

Before you handle the SBC, use the grounding wrist strap provided with the system to

discharge static electricity. Instructions for using the wrist strap are printed on the strap's

envelope.

Always handle the SBC by the edges to help prevent accidental damage that

can be caused by static discharge (Figure 2).

!

Safety

It is important to protect yourself and your equipment before you perform any of the

procedures outlined in this manual.

You should check the configuration before you install the SBC. If the SBC is already installed

in your system and you need to change the configuration, power-off the system and disconnect

all power cords from their source. Follow all safety precautions as outlined by the chassis

manufacturer.

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

Only qualified, experienced electronics personnel should access the interior

of the chassis and handle the equipment.

!

Next...

Before you install the SBC in a chassis, check the following:

Jumper settings, outlined in Step 1, page 8

DIP switch settings, outlined in Step 2, page 10

Pay particular attention to the switch settings. The jumper settings are preconfigured at the

factory and are appropriate for most applications.

6 Service Manual

Chapter 2: 7 Steps to Operation

Figure 2. Safely Handling the SBC

Always handle the SBC by the edges.

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

Service Manual 7

EPC-2100/2101 Single-Board Computer

Step 1: Check Jumper Settings

Overview

Before you install the EPC-2100/2101 onto a passive backplane in a chassis, check the jumper

settings on the SBC (Figure 3).

Definition

A jumper is a small “bridge” that connects two pins on a jumper block. The position of a

jumper affects the device's operational parameters.

Jumper Blocks

The EPC-2100/2101 contains:

Four two-pin jumper blocks (JP1, JP2, JP11, and JP12)

Six three-pin jumper blocks (JP3, JP4, JP5, JP6, JP8, and JP10)

Settings

Table 1. Jumper Block Settings

2-Pin Jumper Blocks

JP1 JP2 Host Bus Speed

None 1—2 66.6 MHz (default)

1—2 None 60.0 MHz

1—2 1—2 50.0 MHz

†

JP11 JP12 Bus/Core Ratio CPU Speed

None None 2/3 100 MHz

None 1—2 1/2 133 MHz

1—2 1—2 2/5 166 MHz

1—2 None 1/3 200 MHz

None None 2/7 233 MHz

†

The Bus Core Ratio is based on the Host Bus Speed at 66.6MHz.

3-Pin Jumper Blocks

Panel Shift Clock

JP3 1—2 Normal (default)

2—3 Inverted

Next Step OS Configuration

1—2 Use this setting when running

JP5 Next Step OS and experiencing

problems with PS/2 mouse

2—3 Normal Operation (default)

Serial 2 Configuration

JP4, JP6, JP8 1—2 RS-422

2—3 RS-232 (default)

Panel Voltage Interface

JP10 1—2 5 V (default)

2—3 3.3 V

8 Service Manual

Chapter 2: 7 Steps to Operation

Figure 3. Jumper Block Locations

����

����

���

���

���

���

�� ������

���

���

���

Table 2. Jumper Block Functions

Jumpers Function

JP1, JP2 Host Bus Speed

2-Pin

JP11, JP12 CPU Speed

JP3 Panel Shift Clock

JP5 Next Step OS Configuration

3-Pin

JP4, JP6, JP8 Serial Port 2 Configuration

JP10 Panel Voltage Interface

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

Service Manual 9

EPC-2100/2101 Single-Board Computer

Step 2: Check Switch Settings

Overview

After you check the jumper settings, check the switch block on the EPC-2100/2101 for proper

settings (Figure 4).

Switch Block

The switch block contains four DIP switches that you can configure to affect the following

items:

Default monitor type

On-board ROM access

CMOS RAM

Configuration ports

Settings

Table 3. Switch Settings

Default Monitor Type

SW1-1 Open Monochrome monitor

Closed (default) Color monitor

On-Board ROM Access

Open (default) Flash memory enabled;

SW1-2 auxiliary ROM mode disabled

Closed Flash memory disabled;

auxiliary ROM mode enabled

CMOS RAM

Open (default) Normal operation of CMOS RAM

SW1-3

Closed Factory default values for the

Setup Utility are loaded into

CMOS RAM

Configuration Ports

Open (default) Configuration ports are mapped to

SW1-4 I/O address 270/271

Closed Configuration ports are mapped to

I/O address 370/371

10 Service Manual

Chapter 2: 7 Steps to Operation

Figure 4. Switch Block Location

���������������������

�����

����

��� ���

��� ���

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

Service Manual 11

EPC-2100/2101 Single-Board Computer

Step 3: Install the SBC

Before you connect any peripheral devices to the EPC-2100/2101, install the SBC onto a

passive backplane in a chassis (Figure 5).

Procedure

Table 4. Installing the SBC

Step Action

Power-off the system and disconnect all power cords.

1 Note: Use the grounding wrist strap provided with the system to discharge static

electricity.

2 Remove the chassis cover.

Detach the circuit card hold-down bracket (if required). This bracket reaches

3

across the tops of the circuit cards and holds them in place.

Locate the “Platform” or “CPU” slot on the passive backplane.

Note: The SBC will not function to its fullest capabilities if it is not installed in the

4

proper slot. For example, if installed in an ISA slot, the SBC will operate, but it will

rd

not be able to communicate with 3 party PCI devices.

Remove the I/O bracket spacer from the rear of the chassis (if required). This

5 spacer occupies the area where the SBCs I/O bracket is accessed from the rear of

the chassis.

Insert the SBC into the chassis with the card edge aligned in the card-end slot and

the I/O bracket in the chassis I/O slot. Lower the SBC to the “Platform” or “CPU”

6 slot on the backplane. Carefully push the SBC connectors into the slot on the

backplane. Ensure that the I/O bracket is accessible through the rear of the

chassis.

7 Secure the I/O bracket to the fastening lip on the chassis.

Note: To install the EPC-2100/2101 onto a passive backplane not manufactured by RadiSys, follow

the instructions provided by the manufacturer of the backplane.

If the SBC is installed into a chassis not manufactured by RadiSys, a custom

cable might be needed to adapt the keyboard header to the wiring in the

chassis. RadiSys does not provide such a cable.

!

The SBC requires a minimum airflow of 200 linear feet per minute (LFM)

unimpeded across the CPU within 0 to 60 °C (32 to 140 °F) ambient

temperature. Operations outside these specifications could void the warranty.

!

12 Service Manual

Chapter 2: 7 Steps to Operation

Figure 5. Installing the SBC

���������������

����������������

�������������

������������������������

������� �������

�����������������

�����������������

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

Service Manual 13

EPC-2100/2101 Single-Board Computer

Step 4: Attach Peripherals to Headers

Overview

After you have installed the EPC-2100/2101 onto a passive backplane in a chassis, attach the

necessary peripheral devices to the appropriate headers on the SBC (Figure 6).

SCSI Drive (EPC-2100 only)

Up to seven SCSI devices can be attached to this header via a 50-conductor flat cable in a

daisy-chain configuration in the EPC-2100.

Note: The “red stripe” on the cable should be near Pin 1 on the header

EIDE Drive

Two EIDE (backwards-compatible with IDE) hard disk drives can be attached to this header

via a 40-conductor flat cable.

Note: The “red stripe” on the cable should be near Pin 1 on the header.

nd

The BIOS will support up to four IDE drives. To use 3 or 4 drives, a 2 controller is

nd

required. The 2 controller must be configured to use IRQ15 and I/O Ports 170-177h.

!

IDE/SCSI

Activity LED

This header connects the IDE or SCSI drive activity LED cable to the SBC.

Note: Pin 1 is the anode; Pin 2 is the cathode.

FDD

Two floppy disk drives can be attached to this header via a 34-conductor flat cable.

Note: The “red stripe” on the cable should be near Pin 1 on the header.

Parallel Port

The parallel port:

Provides a Centronics-compatible printer interface

Supports AT-compatible / bi-directional / EPP operations.

Note: The “red stripe” on the cable should be near Pin 1 on the header.

Keyboard

An AT or PS/2 keyboard can be attached to this header with an appropriate 8-pin cable.

Note: The socket on the RadiSys keyboard cable is numbered in reverse order when

compared to the pinout of the keyboard header on the SBC.

Serial Port 2

A serial device can be attached to this header (16550-compatible) via a 10-conductor flat

cable. If connecting a serial mouse, be sure to use a shielded cable.

Note: The “red stripe” on the cable should be near Pin 1 on the header.

Improperly connecting the cable to this header can cause damage to the

cable, SBC, and external serial device, and could void the warranty.

!

14 Service Manual

Chapter 2: 7 Steps to Operation

Flat Panel Display

A flat panel display such as a back-lit LCD can be attached to this header via a 50-conductor

flat cable.

Note: For more information on the display system, see page 36.

Figure 6. Peripheral Header Locations

23 45 67 8

1

1. Keyboard 4. SCSI Drive (EPC-2100 only) 7. Floppy Drive

2. EIDE Drive 5. Flat Panel Display 8. Serial Port 2

3. IDE/SCSI Activity LED 6. Parallel Port

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

For pin signals and positions, see page 30.

For information on the display system, see page 36.

!

Service Manual 15

EPC-2100/2101 Single-Board Computer

Step 5: Attach Peripherals to Connectors

Overview

After you have attached peripheral devices to the headers on the EPC-2100/2101, attach

devices to connectors on the SBC (Figure 7).

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before connecting or disconnecting any

cables for the equipment.

!

VGA Video

This 15-pin connector provides a standard VGA system interface.

Serial Port 1

This serial port (16550-compatible) is a DE-9 male connector.

Keyboard

A PS/2 keyboard can be attached to this connector.

Mouse

A PS/2 mouse can be attached to this connector.

16 Service Manual

Chapter 2: 7 Steps to Operation

Figure 7. Peripheral Connector Locations

�

#

"

!

A. I/O Bracket 1. VGA Video 3. Serial Port 1

2. PS/2 Mouse 4. PS/2 Keyboard

To avoid damage or injury, always power-off the system and disconnect all

power cords from their power source before handling the equipment.

To help prevent accidental damage that can be caused by static discharge,

always use a grounding wrist strap or other static-dissipating device when

!

accessing the interior of the chassis and handling the equipment.

For pin signals and positions, see page 30.

For information on the display system, see page 36.

!

Service Manual 17

EPC-2100/2101 Single-Board Computer

Step 6: Power-On the System

Overview

After you have installed the EPC-2100/2101 and connected all devices, power-on the system.

No Power

If the system does not power-on, check all power connections and the power source.

If power connections are secure and the power source is adequate, contact Technical Support

at 800-627-8700 or 713-541-8200 between 8:00 a.m. and 5:00 p.m., Central Time, USA. For

more information, see “Customer Support,” page vi.

Startup

After you power-on the system, it will:

Execute the Power-On Self Test (POST) to ensure that the system is functional and

properly configured

Start the operating system

Setup

During the POST, you can access the Setup Utility (Figure 8) to configure the system.

Before using the SBC for the first time, you should verify the system settings

in the Setup Utility. See page 19.

!

18 Service Manual

Chapter 2: 7 Steps to Operation

Step 7: Run the Setup Utility

Overview

The BIOS (Basic Input/Output System) Setup Utility allows you to configure the operations

of the EPC-2100/2101.

Access

To access the Setup Utility, press F2 when prompted during the Power-On Self Test (POST).

Main Menu

The Setup Utility display (Figure 8) contains two areas:

1. Options: The options for the current menu are on the left side of the screen

2. Item Specific Help: Instructions for the current item are on the right side

Menus

The Setup Utility contains a toolbar at the top of the screen that allows you to access the

following menus:

Main

Advanced

Security

Power

Boot

Server

Exit

Options and items for these menus are listed in the tables beginning on page 21.

Boot and Exit

The Boot and Exit menus do not have “default” values. Items for these menus are not included

in the tables below.

Operation

Use the following keys to operate the Setup Utility:

Key Action

Up Arrow ( ↑ ) and Down Arrow ( ↓ ) Select a menu item

Left Arrow ( ← ) and Right Arrow ( → ) Select a menu

Plus ( + ) and Minus ( - ) Change the value of an item

Enter Access a sub-menu (when an item with the sub-menu

character > is highlighted)

F1 Access Help for the Setup Utility

F9 Load default values for the setup options

F10 Save changes and exit

Esc Access the Exit menu

Service Manual 19

EPC-2100/2101 Single-Board Computer

Figure 8. Setup Utility Main Menu

RadiSys CPD Setup Utility

Main Advanced Security Power Boot Server Exit

Item Specific Help

System Time: [ 12:12:00]

System Date: [03/14/2001]

Diskette A: [1.44, 3½"]

Frequently asked questions

What makes Elite.Parts unique?

What kind of warranty will the EPC-2101 have?

Which carriers does Elite.Parts work with?

Will Elite.Parts sell to me even though I live outside the USA?

I have a preferred payment method. Will Elite.Parts accept it?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods