COMPUMOTOR S57-83-MO

Specifications

Input Power

90VAC to 132VAC @ 50/60 Hz

Minimum Motor Hipot

500VAC

Minimum Motor Winding Inductance

2 mH (Compumotor recommends 5 mH measured in series or parallel)

Output Power

Low power: 0.1 to 6A per phase at 170VDC

Features

- 16 user selectable motor resolutions to 50,800 steps/rev

- Anti-resonance eliminates mid-range instability

- Fault output for remote signalling and diagnostics

- Optically isolated step and direction, shutdown and zero phase inputs

- Speeds to 50 rps (3,000 rpm) continuous

- Three-state current control for reduced motor heating

- Torques from 65 to 1,900 oz-in

- User-selectable current waveform for smooth operation

- Zero phase input resets phase currents to the power up positions

Datasheet

Extracted Text

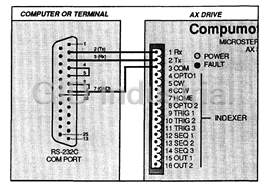

C H A P T E Rˆ Hardware Reference The information in this chapter will enable you to: • Use this chapter as a quick-reference tool for most system specifications (dimensions and performance) • Use this chapter as a quick-reference tool for DIP switch settings Environmental Specifications Drive Temperature 131°F (50°C) measured at the heatsink fins. An internal thermostat will shut down the drive if the unit reaches 158°F (70°C) internally. Current settings in excess of 4A in high ambient temperature environments (above 113°F [45°C]) may require fan cooling to keep the heatsink temperature within allowable limits and to keep the drive from shutting itself down due to over temperature. Motor Temperature 212°F (100°C) maximum allowable motor case temperature. Actual temperature rise is duty cycle dependent. Electrical Specifications Input Power • 90VAC to 132VAC @ 50/60 Hz Output Power • Low power: 0.1 to 6A per phase at 170VDC • High power: 0.2 to 8A per phase at 170VDC Output Type • Two phase MOSFET bipolar (H-bridge) switching at 21 kHz (nominal), pulse width modulated Fault Output • Open-collector • Open emitter • 4N35 V • CE = 35VDC V • CESAT = 0.3VDC • Collector Current = 10 mA minimum • Dissipation = 100 mW maximum Minimum Motor Winding Inductance • 2 mH (Compumotor recommends 5 mH measured in series or parallel) Chapter 4—Hardware Reference 39 Maximum Motor Winding Inductance • None (Compumotor recommends 50 mH measured in series or parallel) Minimum Motor Hipot • 500VAC Step & Direction Signal Specification The inputs are optically isolated and may be driven (activated) by providing a positive pulse to the plus input with respect to the minus input. These inputs may also be differen- tially driven. The input driver must provide a minimum of 6.5 mA (15 mA maximum). Step Pulse Input You must operate the step pulse input within the following guidelines. • 200 nanosecond-pulse minimum • 40% - 60% duty cycle (2 MHz max pulse rate) Direction Input The direction input may change polarity coincident with the last step pulse. The direction input must be stable for at least 2 ms before the drive receives the first pulse. Shutdown & Set Zero Phase Signal Specification The inputs are optically isolated and may be driven (activated) by providing a positive pulse to the plus input with respect to the minus input. The input driver must provide a minimum of 2.5 mA (30 mA maximum). The maximum reverse voltage for this input is 3VDC. Shutdown Input (Amplifier Disable) You may enable this function when the motor is not moving. The input must be active for 100 ms to disable the amplifier. The SHUTDOWN input must be inactive for 100 ms before the first step pulse is received. Set Zero Phase Input This input allows you to reset the motor phase currents to power-up position. It is primarily for linear motor applications. The input must be active for 100 ms to reset the motor phase currents to the zero state. The ZERO PHASE input must be inactive for 100 ms before the first step pulse is received. Fault Output This output is an open-collector, open emitter output from a 4N35 OPTO isolator. The output transistor will conduct when the drive is functioning properly. The transistor will not conduct when any of the following conditions exist: • No power is applied to the drive • There is insufficient AC line voltage (90VAC) • The drive temperature is too high • The drive detects a motor fault • The Shutdown input is enabled + Helpful Hint: Electric Parameters—Outputs This output has the following characteristics: V • CE = 35VDC V • CESAT = 0.3VDC • Collector Current = 10 mA minimum • Dissipation = 100 mW maximum 40 S Drive User Guide Operational Specifications Accuracy ±5 arcminutes typical (unloaded, bidirectional) with Compumotor motors. Repeatability ±5 arcseconds typical (unloaded, unidirectional). Hysteresis Less than 2 arcminutes (0.0334°) unloaded, bidirectional. Rotor Inertia 2 2 6 Size 23 Rotor Inertia oz-in Rotor Inertia (Kg-m x 10- ) S57-51 0.546 9.998 S57-83 1.1 20.1 S57-102 1.69 30.9 2 2 6 Size 34 Rotor Inertia oz-in Rotor Inertia (Kg-m x 10- ) S83-62 3.47 63.4 S83-93 6.76 124 S83-135 10.47 191 2 2 Size 42 Rotor Inertia oz-in Rotor Inertia Kg-cm S106-178 44.0 8.05 S106-205 52.0 9.51 S106-250 63.0 12.14 Rotor Inertia (Compumotor Motors) Motor Current & Torque Speed/torque curves for the S Drive are provided later in this chapter. Motor Size Current Static Torque (in-oz) S57-51 S 1.18 65 S57-51 P 2.28 65 S57-83 S 1.52 100 S57-83 P 3.09 100 S57-102 S 1.71 130 S57-102 P 3.49 130 S83-62 S 2.19 150 S83-62 P 4.42 150 S83-93 S 2.85 290 S83-93 P 5.62 290 S83-135 S 3.47 400 S83-135 P 6.00 343 Motor Specifications (S6) Motor Size Current Static Torque (in-oz) S106-178 S 6.02 1000 S106-178 P 8.0 667 S106-205 S 3.55 1900 S106-205 P 6.99 1900 S106-250 S 6.02 1450 S106-250 P 8.0 967 S: Series Configuration P: Parallel Configuration Motor Specifications (S8) Chapter 4—Hardware Reference 41 Drive Dimensions 3.25 (82.56) 7.04 (178.81) 1.25 Slot for Optional (31.75) #10 mtg screws 0.53 mounting tabs (13.46) Low Power S6 Drive with Heatsink 10.72 9.48 (272.28) (240.79) 10.37 (263.4) 2.74 3.18 (69.60) (80.77) 6.90 (175.26) 4.61 (117.09) 7.04 (178.81) 1.25 Slot for Optional (31.75) #10 mtg screws 0.53 mounting tabs (13.46) High Power S8 Drive with Fan 10.72 9.48 (272.28) (240.79) 10.37 (263.4) 2.74 4.53 (69.60) 6.90 (115.06) (175.26) S Drive Dimensions The fan kit is optional with the low-power version of the S Drive. 42 S Drive User Guide Motor Dimensions 0.215 5.461 Dia. (4) 120 (305) 4-Wire Shielded 0.195 4.952 on 2.625 66.67 BC 2.27 1.956 57.66 47.14 Max 1.502 38.15 Dia View A 1.498 38.05 0.82 20.83 0.83 21.08 0.72 18.29 0.83 18.54 A 0.063 1.60) View A 0.2500 6.35 0.19 4.83 View B 0.2495 6.34 Shaft Dia. (2) 60° #6-32 UNC-2B Thread (4) Equally Spaced on 2.952 (74.98) BCx 0.25 DP View B 1.118 28.40 Dia. Size 23 frame Model A S 57-51 2.0 (5.1) S 57-83 3.1 (7.8) S 57-102 4.0 (10.2) NEMA 23 Motor Dimensions Chapter 4—Hardware Reference 43 120 (305) 8-Wire Shielded 0.228 (5.79) 2.877 73.07) 0.218 (5.54) ( Dia. 2.873 (72.97) 2.730 (69.34) 2.750 (69.85) 3.25 3.40 (86.36) Max. Casting Size View A 1.21 (30.70) 1.23 (31.24) A 1.15 (29.21) 1.17 (29.72) 0.063 (1.60) 0.3750 (9.52) 0.3745 (9.51) Shaft Dia. (2) View B View A 0.19 (4.83) 30∞ View B #6-32 UNC Thread (4) Equally Spaced on 2.952 (74.98) BC - x .25 (6.50) DP Size 34 frame Model A 2.5 (62.0) S 83-62 0.75 (19.05) Dia 3.7 (93.98) S 83-93 x 0.050 (1.27) Deep Bore Min. 5.2 (129.0) S 83-135 NEMA 34 Motor Dimensions 44 S Drive User Guide S106-178 -- S106-250 7.56 (192.02) Single Ended 30° 7.69 (195.32) Double Ended 1.40 1.33 1.36 1.17 0.50-14 NPT (35.56) (33.78) (34.54) (29.72) 0.6250 15.87 0.057 (1.45) 0.6245 15.86 0.067 (1.70) Shaft Dia. 0.5000 (12.70) 0.09 (2.29) Max See Detail View 0.4995 (12.69) #6-32 UNC 2-B Thread Shaft Dia. (4) equally spaced on 2.952 (74.98) BC x 0.25 (6.50) DP 2.186 (155.52) Dia. 0.1255 3.19 0.518 13.16 0.1240 3.15 0.500 12.70 Wide 0.69 (17.53) 4.26 4.20 108.20 106.68 3.50 Max. Max. 88.90 +0.000 0.483 -0.005 Detail View +0.000 12.27 ( ) #404 Woodruff -0.127 0.291 7.39 0.271 6.88 S106-178 Motor Dimensions Chapter 4—Hardware Reference 45 S106-205 0.573 (14.55) 0.09 (2.28) Max 30° 0.553 (14.05) 0.5 (12.70) 0.4995 (12.69) 0.067 (1.70) 0.50-14NPT Shaft Dia. 0.057 (14.05) 4.25 (107.95) Dia. Max #6 - 32 UNC-2B Thread 2.23 (4) Equallty spaced on 0.6250 (15.87) 2.15 2.952 (74.980) BC 0.6245 (15.86) 1.29 (56.64) Shaft Dia. x 0.25 (6.50) DP 8.160 (207.26) Max. 1.21 (54.61) See Detail View (32.76) (30.73) 2.187 (55.55) 3.50 Detail View (88.90) 2.186 (55.52) Sq. 1.41 (35.41) 1.25 (31.75) 0.1875 (4.75) +0.000 -0.002 4.40 (111.76) 0.705 (17.91) Sq aMax. 0.1875 +0.000 (4.75) -0.002 +0.000 -0.002 0.333 (8.46) 0.323 (8.20) (4) Holes S106-205 Motor Dimensions 46 S Drive User Guide DIP Switch Summary The S Drive has two sets of DIP switches (refer to Chapter ´). Each set of DIP switches has eight individual switches. The first set of switches is referred to as SW1 and the second set as SW2. The individual switch will be preceded by the # symbol. Hence, the third switch on SW1 is referred to as SW1-#3, while the third switch on SW2 is referred to as SW2-#3. Switch # Function SW1-#1 Current—most significant bit SW1-#2 Current SW1-#3 Current SW1-#4 Current SW1-#5 Current SW1-#6 Current—least significant bit SW1-#7 Auto Standby SW1-#8 Auto Standby SW2-#1 Motor Resolution SW2-#2 Motor Resolution SW2-#3 Motor Resolution SW2-#4 Motor Resolution SW2-#5 Waveform SW2-#6 Waveform SW2-#7 Waveform SW2-#8 Auto Test = on, Normal operation = off DIP Switch Summary Motor Current Motor Size Current SW1-#1 SW1-#2 SW1-#3 SW1-#4 SW1-#5 SW1-#6 S57-51S 1.18 off off on on off off S57-51P 2.28 off on on off off off S57-83S 1.52 off on off off off off S57-83P 3.09 on off off off off off S57-102S 1.71 off on off off on off S57-102P 3.47 on off off on off off S83-62S 2.19 off on off on on on S83-62P 4.42 on off on on on off S83-93S 2.85 off on on on on off S83-93P 5.62 on on on off on on S83-135S 3.47 on off off on off off S83-135P 6.00 on on on on on on S: Series Configuration P: Parallel Configuration S6 Drive Motor Current (Compumotor Motors) Motor Size Current SW1-#1 SW1-#2 SW1-#3 SW1-#4 SW1-#5 SW1-#6 S106-178S 6.02 on off on on on on S106-178P 8.0 on on on on on on S106-205S 3.55 off on on on off off S106-205P 6.99 on on off on on on S106-250S 6.23 on on off off off on S106-250P 8.0 on on on on on on S: Series Configuration P: Parallel Configuration S8 Drive Motor Current (Compumotor Motors) Chapter 4—Hardware Reference 47 Low-Power S6 Drive Current SW1 SW2 SW3 SW4 SW5 SW6 Current SW1 SW2 SW3 SW4 SW5 SW6 0.04 off off off off off off 3.09 on off off off off off 0.13 off off off off off on 3.19 on off off off off on 0.23 off off off off on off 3.28 on off off off on off 0.32 off off off off on on 3.38 on off off off on on 0.42 off off off on off off 3.47 on off off on off off 0.51 off off off on off on 3.57 on off off on off on 0.61 off off off on on off 3.66 on off off on on off 0.70 off off off on on on 3.76 on off off on on on 0.80 off off on off off off 3.85 on off on off off off 0.89 off off on off off on 3.95 on off on off off on 0.99 off off on off on off 4.04 on off on off on off 1.08 off off on off on on 4.14 on off on off on on 1.18 off off on on off off 4.23 on off on on off off 1.27 off off on on off on 4.33 on off on on off on 1.37 off off on on on off 4.42 on off on on on off 1.46 off off on on on on 4.51 on off on on on on 1.52 off on off off off off 4.58 on on off off off off 1.62 off on off off off on 4.68 on on off off off on 1.71 off on off off on off 4.77 on on off off on off 1.81 off on off off on on 4.86 on on off off on on 1.90 off on off on off off 4.96 on on off on off off 2.00 off on off on off on 5.05 on on off on off on 2.09 off on off on on off 5.15 on on off on on off 2.19 off on off on on on 5.24 on on off on on on 2.28 off on on off off off 5.34 on on on off off off 2.38 off on on off off on 5.43 on on on off off on 2.47 off on on off on off 5.53 on on on off on off 2.57 off on on off on on 5.62 on on on off on on 2.66 off on on on off off 5.72 on on on on off off 2.76 off on on on off on 5.81 on on on on off on 2.85 off on on on on off 5.91 on on on on on off 2.95 off on on on on on 6.00 on on on on on on Setting S6 Drive Motor Current (Non-Compumotor Motors) High-Power S8 Drive Current SW1 SW2 SW3 SW4 SW5 SW6 Current SW1 SW2 SW3 SW4 SW5 SW6 0.05 off off off off off off 4.12 on off off off off off 0.18 off off off off off on 4.25 on off off off off on 0.30 off off off off on off 4.38 on off off off on off 0.43 off off off off on on 4.50 on off off off on on 0.56 off off off on off off 4.63 on off off on off off 0.69 off off off on off on 4.75 on off off on off on 0.81 off off off on on off 4.89 on off off on on off 0.93 off off off on on on 5.01 on off off on on on 1.06 off off on off off off 5.14 on off on off off off 1.19 off off on off off on 5.26 on off on off off on 1.31 off off on off on off 5.39 on off on off on off 1.44 off off on off on on 5.51 on off on off on on 1.59 off off on on off off 5.64 on off on on off off 1.69 off off on on off on 5.77 on off on on off on 1.82 off off on on on off 5.90 on off on on on off 1.94 off off on on on on 6.02 on off on on on on 2.03 off on off off off off 6.11 on on off off off off 2.16 off on off off off on 6.23 on on off off off on 2.28 off on off off on off 6.36 on on off off on off 2.41 off on off off on on 6.48 on on off off on on 2.54 off on off on off off 6.61 on on off on off off 2.66 off on off on off on 6.73 on on off on off on 2.79 off on off on on off 6.87 on on off on on off 2.91 off on off on on on 6.99 on on off on on on 3.04 off on on off off off 7.12 on on on off off off 3.17 off on on off off on 7.24 on on on off off on 3.297 off on on off on off 7.37 on on on off on off 3.42 off on on off on on 7.49 on on on off on on 3.55 off on on on off off 7.62 on on on on off off 3.67 off on on on off on 7.75 on on on on off on 3.80 off on on on on off 7.87 on on on on on off 3.93 off on on on on on 8.00 on on on on on on Setting S8 Drive Motor Current (Non-Compumotor Motors) 48 S Drive User Guide Automatic Standby Function Current SW1-#7 SW1-#8 * Full Current off off 75% on off 50% off on 25% on on * Default Setting Automatic Standby Function Motor Resolutions Resolution SW2-#1 SW2-#2 SW2-#3 SW2-#4 50,800 steps off off off on 50,000 steps off off on off 36,000 steps off off on on 25,600 steps off on off off 25,400 steps off on off on * 25,000 steps off off off off 21,600 steps off on on off 20,000 steps off on on on 18,000 steps on off off off 12,800 steps on off off on 10,000 steps on off on off 5,000 steps on off on on 2,000 steps on on off off 1,000 steps on on off on 400 steps on on on off 200 steps on on on on * Default Setting Motor Resolution Settings Motor Waveforms Waveform Shape SW2-#5 SW2-#6 SW2-#7 Pure Sine on on off -2% 3rd harmonic on off on * -4% 3rd harmonic off off off -4% 3rd harmonic on on on -4% 3rd harmonic on off off -6% 3rd harmonic off on on -8% 3rd harmonic off on off -10% 3rd harmonic off off on * Default Setting Motor Waveform Settings Automatic Test Function • SW2-#8 OFF Disables Auto Test SW2-#8 ON Enables Auto Test * Default Setting Motor Performance Specifications S Series motors are designed to allow you to change the motor winding configuration easily. The following performance indicate that different performance levels can be obtained by connecting the step motor windings in series or parallel. Use caution when you run motors in a parallel configuration. Sustained operation at high speeds may cause the motor to overheat due to electrical pole heating. Chapter 4—Hardware Reference 49 Power Power Power Power Power Power Power Power Power oz-in (N-m) (HP) S57–51, SX47-51 & SXF57-51 S83–135, SX83-135 75 (0.53) oz-in (N-m) (HP) & SXF83-135 500 (3.50) Parallel* 60 (0.42) 400 (2.80) 45 (0.32) Parallel* Series 300 (2.10) 30 (0.21) 0.14 Parallel 200 (1.40) 0.54 Parallel Series 15 (0.11) 0.07 Series 100 (0.70) 0.27 Series 0 0 10 20 30 40 50 0 Speed-RPS 0 10 20 30 40 50 Speed-RPS S106–178, SX106-178 oz-in (N-m) (HP) oz-in (N-m) (HP) S57–83, SX57-83 & SXF57-83 & SXF106-178 125 (0.88) 1250 (8.75) Parallel* Series 100 (0.70) 1000 (7.00) 75 (0.53) 750 (5.25) Series Parallel* 50 (0.35) 0.20 Parallel (3.50) 0.80 Parallel 500 25 (0.18) 0.10 Series 250 (1.75) 0.40 Series 0 0 0 10 20 30 40 50 0 10 20 30 40 50 Speed-RPS Speed-RPS S106–250, SX106-250 oz-in (N-m) (HP) oz-in (N-m) (HP) S57–102, SX57-102, SXF57-102 & SXF106-250 150 (1.05) 1500 (10.50) Series Parallel* 120 (0.84) 1200 (8.40) Parallel* 90 (0.63) 900 (6.30) Series 60 (0.42) 0.25 Parallel 600 (4.20) 1.08 Parallel 30 (0.21) 0.13 Series 300 (2.10) 0.54 Series 0 0 0 10 20 30 40 50 0 10 20 30 40 50 Speed-RPS Speed-RPS S106–205, SX106-205 oz-in (N-m) (HP) oz-in (N-m) (HP) S83–62, SX83-62, SXF83-62 & SXF106-205 200 (1.40) 2000 (14.00) 160 (1.12) 1600 (11.20) Parallel* 120 (0.84) 1200 (8.40) Series Parallel* 80 (0.56) 0.32 Parallel 800 (5.60) 0.67 Parallel Series 40 (0.28) 0.16 Series 400 (2.80) 0.33 Series 0 0 0 10 20 30 40 50 0 10 20 30 40 50 Speed-RPS Speed-RPS oz-in (N-m) (HP) S83–93, SX83-93 & SXF83-93 400 (2.80) *Parallel connected motors are limited to 50% 320 (2.24) duty cycle when operated above 5 rps. Parallel* For greater than 50% duty cycle above 5 rps, you 240 (1.68) must connect the motor in series. Series 160 (1.12) 0.46 Parallel Fan cooling the motor will increase duty cycles above 5 rps. 80 (0.56) 0.23 Series 0 0 10 20 30 40 50 Speed-RPS 50 S Drive User Guide Torque Torque Torque Torque Torque Torque Torque Torque Torque

Frequently asked questions

What makes Elite.Parts unique?

What kind of warranty will the S57-83-MO have?

Which carriers does Elite.Parts work with?

Will Elite.Parts sell to me even though I live outside the USA?

I have a preferred payment method. Will Elite.Parts accept it?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods