ACCURIDE 2601

Description

Low profile slide with hold-in detent

Part Number

2601

Price

Request Quote

Manufacturer

ACCURIDE

Lead Time

Request Quote

Category

PRODUCTS - 2

Datasheet

Extracted Text

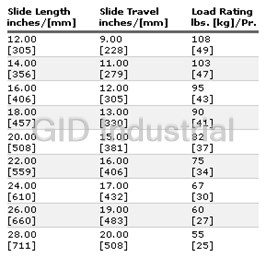

���������� ® APPLICATIONS: Use model 2601 whenever a full extension, Full Extension, Hold-In Detent very low profile slide is required. Ideal for use in tool boxes, Very Low Profile laboratory furniture, and store fixtures. Not suitable for flat Up to 75 lb.** Capacity mounting. This product is covered by U.S. (6,254,209) Up to [34 kg.]** Capacity and various foreign patents issued and/or pending. This mounting hole is not accessible on model 2601-12 [300mm]. 1 2 This mounting slot is only available on model 2601-16 [400mm]. 3 This mounting slot is not accessible on model 2601-16 [400mm]. Closed Position Flush or Under Travel E D Slide Length .85 C E [21.6] .85 B D TYP. [21.6] 1.02 C A .35 [26.0] 1.02 .35 B .496 1.35 [9.0] [26.0] [9.0] [12.6] A [34.3] TYP. TYP. 1.03 [26.3] .291 .85 .496 .250 DIA. 1.35 .180 X .312 2 1.73 .180 [7.4] [21.6] [12.6] [6.3] TYP. [34.3] .50 [4.6 X 7.9] [44.0] [4.6] TYP. DIA. TYP. [12.7] .180 TYP. TYP. 3 Access TYP. .180 X .312 .59 .250 DIA. .85 [4.6] 1 TYP. [4.6 X 7.9] [15.2] [6.3] TYP. [21.6] TYP. INCHES [mm] Finish Bright electro-zinc plating (C) or Sidespace .50” +.030/ -.000 black zinc* (CB) finish available [12.7 +0.8/ -0.0] Length Even lengths from 8” to 22” Mounting Side [200mm to 550mm] Hardware #6 truss head screw Travel Full extension Movement Steel ball bearings Height 1.03” (26.3mm) Features Hold-in detent, silenced Load See chart movement in and out * Minimum order quantities may apply. ** Load rating based on a 16" wide drawer cycled 10,000 times. Part Slide Slide Load Rating A B C D E Number Length Travel lb [kg]/pair ** 7.87 8.23 35 lb 5.04 2601-8 [200] [209] [16 kg] [128.0] 9.84 10.20 50 lb 5.04 2601-10 [250] [259] [23 kg] [128.0] 11.81 12.13 70 lb 5.04 8.82 2601-12 [300] [308] [32 kg] [128.0] [224.0] 13.78 14.06 75 lb 5.04 8.82 2601-14 [350] [357] [34 kg] [128.0] [224.0] 15.75 15.98 70 lb 5.04 8.82 12.60 2601-16 [400] [406] [32 kg] [128.0] [224.0] [320.0] 17.72 17.95 65 lb 5.04 8.82 13.86 2601-18 [450] [456] [30 kg] [128.0] [224.0] [352.0] 19.69 19.88 63 lb 5.04 8.82 13.86 16.38 2601-20 [500] [505] [29 kg] [128.0] [224.0] [352.0] [416.0] 21.65 21.81 60 lb 5.04 8.82 13.86 17.64 19.25 2601-22 [550] [554] [27 kg] [128.0] [224.0] [352.0] [448.0] [489.0] ������������������������� ��������������������������� Complete your slide order for model 2601 by specifying the Install the Cabinet Member following: 1. Mark a horizontal line in the cabinet sidewall at least 5/8” [15.9mm] up from the cabinet floor or at least 5/8” [15.9mm] 200 Pair C 2601 -18 D down from the top of the drawer side. Mark a point on the line 2-3/8” [60.2mm] in from the cabinet front. This will position Total Slides Required the slide flush with the cabinet opening. For inset drawers, Slide Finish add the drawer front thickness to the 2-3/8” [60.2mm] Slide Model Slide Length dimension. See Figure 1. Optional Polybag Packaging Figure 1 ��������� Distributor (D) Pack: All lengths are packaged 10 pair per box. Cabinet Flush Polybag includes one pair of slides and installation sheet. Side Bulk (P) Pack: All lengths are packaged 15 pair per box. �������������� 1/8" Use #6 Slide members: Cold rolled steel 5/8" [3.2] truss head 2-1/2" 2-3/8" [15.9] Ball retainers: Cold rolled steel screws [63.5] [60.2] Min. Ball bearings: Carburized steel Note: Specifications, materials, prices, terms, and delivery are subject to change without notice. 2. Measure the distance between the front and rear horizontal slots on the slide. Mark this measurement on the horizontal line beginning at the first mark. 3. Install #6 truss head screw through the front and rear horizontal slots. Adjust for horizontal position. 4. Install screws in round holes, front and rear of cabinet member. For longer slides (18" [450mm] and over), install additional screws in the central holes. Install the Drawer Member 1. Mark a horizontal line on the drawer side in line with the slide center line. 2. Mark a point on the line 2-1/2” [63.5mm] back from the drawer front. Measure the distance between the front and rear horizontal slots on the slide. Mark this measurement on the horizontal line beginning at the first mark. 3. Install a screw through the first horizontal slot. See Figure 1. 4. Install screw and adjust location of drawer. 5. Install screws in the round holes, front and rear of drawer member. For longer slides (18" [450mm] and over), install additional screws in the central holes. NOTE: To access the additional mounting holes in the cabinet and drawer members of the slide, it is necessary to move the intermediate member to line up the access hole and the mounting hole. ACCURIDE INTERNATIONAL INC. 12311 Shoemaker Avenue Santa Fe Springs, CA 90670 TEL (562) 903-0200 FAX (562) 903-0208 www.accuride.com Manufacturing, Engineering, and Sales United States Germany Japan Mexico United Kingdom Copyright © 2002 Accuride International Inc. Printed in U.S.A. 3700-1062(9394)-MK549-R3-0502 Copyright © 2002 Accuride International Inc. Printed in U.S.A. 3700-9394(1062)-MK051-R3-0502

Frequently asked questions

What makes Elite.Parts unique?

What kind of warranty will the 2601 have?

Which carriers does Elite.Parts work with?

Will Elite.Parts sell to me even though I live outside the USA?

I have a preferred payment method. Will Elite.Parts accept it?

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods