STMICROELECTRONICS ST10F269Z2Q6

Specifications

FAST AND FLEXIBLE BUS

Programmable External Bus Characteristics for Different Address Ranges | 8-bit or 16-bit External Data Bus | Multiplexed or Demultiplexed External Address/data Buses | Five Programmable Chip-select Signals | Hold-acknowledge Bus Arbitration Support

HIGH PERFORMANCE 32 OR 40 MHZ CPU WITH DSP FUNCTION

16-bit CPU With 4-stage Pipeline | 50ns (or 62.5ns) Instruction Cycle Time at 40MHz (or 32MHz) Max CPU Clock | Multiply/accumulate Unit (Mac) 16 X 16-bit Multiplication, 40-bit Accumulator | Repeat Unit | Enhanced Boolean Bit Manipulation Facilities | Additional Instructions to Support HLL and Operating Systems | Single-cycle Context Switching Support

INTERRUPT

8-channel Peripheral Event Controller for Single Cycle Interrupt Driven Data Transfer | 16-priority-level Interrupt System with 56 Sources, Sampling Rate Down to 25ns at 40MHz (31.25ns at 32MHz)

MEMORY ORGANIZATION

128K or 256K Byte On-chip Flash Memory Single Voltage With Erase/program Controller | Up to 1K Erasing/programming Cycles | Up to 16 MByte Linear Address Space For Code And Data (5 MBytes With CAN) | 2K Byte On-chip Internal RAM (IRAM) | 10K Byte On-chip Extension RAM (XRAM)

TIMERS

Two Multi-functional General Purpose Timer Units with 5 Timers

Features

- 16 x 16-bit signed/unsigned parallel multiplier

- 40-bit accumulator

- 40-bit signed arithmetic unit with automatic saturation mode

- 8-bit left/right shifter

- New addressing modes including a double indirect addressing mode with pointer post-modification

- New transfer instructions CoSTORE (for fast access to the MAC SFRs) and CoMOV (for fast memory to memory table transfer)

- One-cycle execution for all MAC operations

- Parallel Data Move: this mechanism allows one operand move during Multiply-Accumulate instructions without penalty

Datasheet

Extracted Text

ST10F269Zx

16-BIT MCU WITH MAC UNIT,

128K to 256K BYTE FLASH MEMORY AND 12K BYTE RAM

DATASHEET

■ HIGH PERFORMANCE 32 OR 40 MHZ CPU WITH

DSP FUNCTION

– 16-bit CPU With 4-stage Pipeline

– 50ns (or 62.5ns) Instruction Cycle Time at 40MHz (or

32MHz) Max CPU Clock

– Multiply/accumulate Unit (Mac) 16 X 16-bit Multipli-

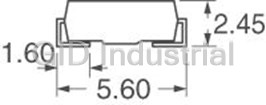

PQFP144 (28 x 28

mm) (Plastic Quad Flat Pack)

cation, 40-bit Accumulator

– Repeat Unit

– Enhanced Boolean Bit Manipulation Facilities

– Additional Instructions to Support HLL and Operat-

ing Systems

– Single-cycle Context Switching Support

■ MEMORY ORGANIZATION

TQFP144 (20 x 20 x 1.40 mm) (Thin Quad Flat Pack)

– 128K or 256K Byte On-chip Flash Memory Single Volt-

■ TWO CAN 2.0B INTERFACES OPERATING ON

age With Erase/program Controller

ONE OR TWO CAN BUSSES (30 OR 2x15

– Up to 1K Erasing/programming Cycles MESSAGE OBJECTS)

■ FAIL-SAFE PROTECTION

– Up to 16 MByte Linear Address Space For Code And

Data (5 MBytes With CAN)

– Programmable Watchdog Timer

– 2K Byte On-chip Internal RAM (IRAM)

– Oscillator Watchdog

– 10K Byte On-chip Extension RAM (XRAM)

■ ON-CHIP BOOTSTRAP LOADER

■ FAST AND FLEXIBLE BUS

■ CLOCK GENERATION

– Programmable External Bus Characteristics for Dif-

– On-chip PLL

ferent Address Ranges

– Direct or Prescaled Clock Input

– 8-bit or 16-bit External Data Bus

■ REAL TIME CLOCK

– Multiplexed or Demultiplexed External Address/data

■ UP TO 111 GENERAL PURPOSE I/O LINES

Buses

– Individually Programmable as Input, Output or Spe-

– Five Programmable Chip-select Signals

cial Function

– Hold-acknowledge Bus Arbitration Support

– Programmable Threshold (Hysteresis)

■ INTERRUPT

■ IDLE AND POWER DOWN MODES

– 8-channel Peripheral Event Controller for Single Cy-

■ SINGLE VOLTAGE SUPPLY: 5V ±10% (EMBEDDED

cle Interrupt Driven Data Transfer

REGULATOR FOR 2.7 or 3.3 V CORE SUPPLY).

– 16-priority-level Interrupt System with 56 Sources,

°

■ TEMPERATURE RANGES: -40 +125 C / -40 to 85°C

Sampling Rate Down to 25ns at 40MHz (31.25ns at

■ 144-PIN PQFP/TQFP PACKAGES

32MHz)

16

32

■ TIMERS

2K Byte

128K or 256KByte

16

Internal

Flash Memory CPU-Core and MAC Unit

RAM

– Two Multi-functional General Purpose Timer Units

with 5 Timers

Watchdog

16

■ TWO 16-CHANNEL CAPTURE / COMPARE UNITS 10K Byte PEC

Oscillator

XRAM

and PLL

■ A/D CONVERTER

CAN1_RXD

CAN1 XTAL1 XTAL2

– 16-channel 10-bit CAN1_TXD

Interrupt Controller 16

Voltage

3.3V

CAN2_RXD

CAN2

Regulator

– 4.85µs Conversion Time at 40MHz CPU Clock CAN2_TXD

(6.06µs at 32MHz)

■ 4-CHANNEL PWM UNIT

16

■ SERIAL CHANNELS

16

– Synchronous / Asynchronous Serial Channel

16

BRG BRG

– High-speed Synchronous Channel

8

Port 6 Port 5 Port 3 Port 7 Port 8

8 16 15 8 8

September 2003 1/184

Port 4 Port 1 Port 0

External Bus

Controller

10-Bit ADC

GPT2 GPT1

ASC usart

SSC

PWM

CAPCOM2

CAPCOM1

Port 2

ST10F269

TABLE OF CONTENTS PAGE

ST10F269

1 - Introduction ................................................................................................................. 6

2 - Pin Data ...................................................................................................................... 7

3 - Functional Description .............................................................................................. 13

4 - Memory Organization ............................................................................................... 14

5 - Internal Flash Memory .............................................................................................. 17

5.1 - OVERVIEW ................................................................................................................... 17

5.2 - OPERATIONAL OVERVIEW ........................................................................................17

5.3 - ARCHITECTURAL DESCRIPTION .............................................................................. 19

5.3.1 - Read Mode .................................................................................................... 19

5.3.2 - Command Mode ............................................................................................ 19

5.3.3 - Ready/Busy Signal ........................................................................................19

5.3.4 - Flash Status Register .................................................................................... 19

5.3.5 - Flash Protection Register .............................................................................. 21

5.3.6 - Instructions Description .................................................................................21

5.3.7 - Reset Processing and Initial State ................................................................ 26

5.4 - FLASH MEMORY CONFIGURATION .......................................................................... 26

5.5 - APPLICATION EXAMPLES .......................................................................................... 26

5.5.1 - Handling of Flash Addresses ........................................................................ 26

5.5.2 - Basic Flash Access Control ........................................................................... 27

5.5.3 - Programming Examples ................................................................................ 28

5.6 - BOOTSTRAP LOADER .............................................................................................. 31

5.6.1 - Entering the Bootstrap Loader ...................................................................... 31

5.6.2 - Memory Configuration After Reset ................................................................ 32

5.6.3 - Loading the Startup Code ............................................................................. 33

5.6.4 - Exiting Bootstrap Loader Mode .....................................................................33

5.6.5 - Choosing the Baud Rate for the BSL ............................................................ 34

6 - Central Processing Unit (CPU) ................................................................................. 35

6.1 - MULTIPLIER-ACCUMULATOR UNIT (MAC) ............................................................... 36

6.1.1 - Features ........................................................................................................ 37

6.1.1.1 -Enhanced Addressing Capabilities .................................................. 37

6.1.1.2 -Multiply-Accumulate Unit.................................................................. 37

6.1.1.3 -Program Control............................................................................... 37

6.2 - INSTRUCTION SET SUMMARY .................................................................................. 38

6.3 - MAC COPROCESSOR SPECIFIC INSTRUCTIONS ................................................... 39

7 - External Bus Controller ............................................................................................. 43

7.1 - PROGRAMMABLE CHIP SELECT TIMING CONTROL ............................................... 43

7.2 - READY PROGRAMMABLE POLARITY ....................................................................... 43

8 - Interrupt System ....................................................................................................... 45

8.1 - EXTERNAL INTERRUPTS ........................................................................................... 45

8.2 - INTERRUPT REGISTERS AND VECTORS LOCATION LIST ..................................... 46

8.3 - INTERRUPT CONTROL REGISTERS ......................................................................... 47

2/184

ST10F269

TABLE OF CONTENTS PAGE

8.4 - EXCEPTION AND ERROR TRAPS LIST .....................................................................48

9 - Capture/Compare (CAPCOM) Units ......................................................................... 49

10 - General Purpose Timer Unit ..................................................................................... 52

10.1 - GPT1 ............................................................................................................................. 52

10.2 - GPT2 ............................................................................................................................. 53

11 - PWM Module ............................................................................................................ 56

12 - Parallel Ports ............................................................................................................ 57

12.1 - INTRODUCTION ...........................................................................................................57

12.2 - I/O’S SPECIAL FEATURES .......................................................................................... 59

12.2.1 - Open Drain Mode .......................................................................................... 59

12.2.2 - Input Threshold Control ............................................................................... 59

12.2.3 - Output Driver Control .................................................................................. 60

12.2.4 - Alternate Port Functions ................................................................................ 62

12.3 - PORT0 .......................................................................................................................... 63

12.3.1 - Alternate Functions of PORT0 ...................................................................... 64

12.4 - PORT1 .......................................................................................................................... 66

12.4.1 - Alternate Functions of PORT1 ...................................................................... 66

12.5 - PORT 2 .........................................................................................................................68

12.5.1 - Alternate Functions of Port 2 ......................................................................... 68

12.6 - PORT 3 .........................................................................................................................71

12.6.1 - Alternate Functions of Port 3 ......................................................................... 73

12.7 - PORT 4 .........................................................................................................................76

12.7.1 - Alternate Functions of Port 4 ......................................................................... 77

12.8 - PORT 5 .........................................................................................................................80

12.8.1 - Alternate Functions of Port 5 ......................................................................... 81

12.8.2 - Port 5 Schmitt Trigger Analog Inputs ............................................................ 82

12.9 - PORT 6 .........................................................................................................................82

12.9.1 - Alternate Functions of Port 6 ......................................................................... 83

12.10 - PORT 7 .........................................................................................................................86

12.10.1 - Alternate Functions of Port 7 ......................................................................... 87

12.11 - PORT 8 .........................................................................................................................90

12.11.1 - Alternate Functions of Port 8 ......................................................................... 91

13 - A/D Converter ........................................................................................................... 93

14 - Serial Channels ........................................................................................................ 95

14.1 - ASYNCHRONOUS / SYNCHRONOUS SERIAL INTERFACE (ASCO) ....................... 95

14.1.1 - ASCO in Asynchronous Mode ....................................................................... 95

14.1.2 - ASCO in Synchronous Mode ........................................................................ 98

14.2 - HIGH SPEED SYNCHRONOUS SERIAL CHANNEL (SSC) ...................................... 101

15 - CAN Modules .......................................................................................................... 103

15.1 - CAN MODULES MEMORY MAPPING .......................................................................103

15.1.1 - CAN1 ...........................................................................................................103

15.1.2 - CAN2 ...........................................................................................................103

15.2 - CAN BUS CONFIGURATIONS ................................................................................... 103

3/184

ST10F269

TABLE OF CONTENTS PAGE

16 - Real Time Clock ..................................................................................................... 105

16.1 - RTC REGISTERS .......................................................................................................106

16.1.1 - RTCCON: RTC Control Register .................................................................106

16.1.2 - RTCPH & RTCPL: RTC PRESCALER Registers ....................................... 108

16.1.3 - RTCDH & RTCDL: RTC DIVIDER Counters ...............................................108

16.1.4 - RTCH & RTCL: RTC Programmable COUNTER Registers ........................109

16.1.5 - RTCAH & RTCAL: RTC ALARM Registers ................................................. 110

16.2 - PROGRAMMING THE RTC ........................................................................................110

17 - Watchdog Timer ..................................................................................................... 112

18 - System Reset ......................................................................................................... 114

18.1 - LONG HARDWARE RESET .......................................................................................114

18.1.1 - Asynchronous Reset ...................................................................................114

18.1.2 - Synchronous Reset (RSTIN pulse > 1040TCL and RPD pin at high level) .115

18.1.3 - Exit of Long Hardware Reset ......................................................................116

18.2 - SHORT HARDWARE RESET .....................................................................................116

18.3 - SOFTWARE RESET ...................................................................................................117

18.4 - WATCHDOG TIMER RESET ......................................................................................117

18.5 - RSTOUT, RSTIN, BIDIRECTIONAL RESET ..............................................................118

18.5.1 - RSTOUT Pin ...............................................................................................118

18.5.2 - Bidirectional Reset ......................................................................................118

18.5.3 - RSTIN pin ....................................................................................................118

18.6 - RESET CIRCUITRY ....................................................................................................118

19 - Power Reduction Modes ......................................................................................... 122

19.1 - IDLE MODE ................................................................................................................122

19.2 - POWER DOWN MODE ..............................................................................................122

19.2.1 - Protected Power Down Mode ......................................................................122

19.2.2 - Interruptible Power Down Mode ..................................................................122

20 - Special Function Register Overview ....................................................................... 125

20.1 - IDENTIFICATION REGISTERS ..................................................................................131

20.2 - SYSTEM CONFIGURATION REGISTERS ................................................................132

21 - Electrical Characteristics ........................................................................................ 139

21.1 - ABSOLUTE MAXIMUM RATINGS .............................................................................. 139

21.2 - PARAMETER INTERPRETATION .............................................................................139

21.3 - DC CHARACTERISTICS ............................................................................................139

21.3.1 - A/D Converter Characteristics .....................................................................144

21.3.2 - Conversion Timing Control ........................................................................145

21.4 - AC CHARACTERISTICS ............................................................................................146

21.4.1 - Test Waveforms .........................................................................................146

21.4.2 - Definition of Internal Timing .........................................................................146

21.4.3 - Clock Generation Modes .............................................................................148

21.4.4 - Prescaler Operation ....................................................................................149

21.4.5 - Direct Drive ..................................................................................................149

21.4.6 - Oscillator Watchdog (OWD) ........................................................................ 149

4/184

ST10F269

TABLE OF CONTENTS PAGE

21.4.7 - Phase Locked Loop .....................................................................................149

21.4.8 - External Clock Drive XTAL1 ........................................................................150

21.4.9 - Memory Cycle Variables .............................................................................151

21.4.10 - Multiplexed Bus ........................................................................................... 152

21.4.11 - Demultiplexed Bus ......................................................................................160

21.4.12 - CLKOUT and READY .................................................................................168

21.4.13 - External Bus Arbitration ...............................................................................171

21.4.14 - High-Speed Synchronous Serial Interface (SSC) Timing ............................174

21.4.14.1Master Mode ................................................................................ 174

21.4.14.2Slave mode .................................................................................. 175

22 - Package Mechanical Data ..................................................................................... 178

23 - Ordering Information ............................................................................................... 180

ERRATA SHEET

1 - DESCRIPTION ....................................................................................................... 181

2 - FUNCTIONAL PROBLEMS .................................................................................... 181

2.1 - PWRDN.1 - EXECUTION OF PWRDN INSTRUCTION .............................................181

2.2 - MAC.9 - COCMP INSTRUCTION INVERTED OPERANDS .......................................182

2.3 - MAC.10 - E FLAG EVALUATION FOR COSHR AND COASHR INSTRUCTIONS WHEN

SATURATION MODE IS ENABLED ........................................................................... 182

2.4 - ST_PORT.3 - BAD BEHAVIOR OF HYSTERESIS FUNCTION ON INPUT FALLING

EDGE ..........................................................................................................................183

3 - DEVIATIONS FROM DC/AC PRELIMINARY SPECIFICATION ............................ 183

4 - ERRATA SHEET VERSION INFORMATION ......................................................... 183

5/184

1 - INTRODUCTION ST10F269

1 - INTRODUCTION

The ST10F269 is a derivative of the frees up the CPU during programming or

STMicroelectronics ST10 family of 16-bit erasing the Flash.

single-chip CMOS microcontrollers. It combines

– 128-KByte Flash Option

high CPU performance (up to 20 million

– Two dedicated pins (DC1 and DC2) on the

instructions per second) with high peripheral

144-pin package are used for decoupling the

functionality and enhanced I/O-capabilities. It also

internally generated 3.3V (or 2.7V on TQFP144

provides on-chip high-speed single voltage Flash

devices) core logic supply. Do not connect

memory, on-chip high-speed RAM, and clock

these two pins to 5.0V external supply.

generation via PLL. Instead, these pins should be connected to a

decoupling capacitor (ceramic type, value ≥ 330

ST10F269 is processed in 0.35μm CMOS

nF).

technology. The MCU core and the logic is

– The A/D Converter characteristics are different

supplied with a 5V to 3.3V on chip voltage

from previous ST10 derivatives ones. Refer to

regulator on PQFP144 devices (or 5V to 2.7V on

Section 21.3.1 -.

TQFP144 devices). The part is supplied with a

– The AC and DC parameters are adapted to the

single 5V supply and I/Os work at 5V.

40MHz maximum CPU frequency on PQFP144

The device is upward compatible with the

devices (32MHz on TQFP144 devices). The

ST10F168 device, with the following set of characterization is performed with C = 50pF

L

differences: max on output pins. Refer to Section 21.3 -.

– In order to reduce EMC, the rise/fall time and the

– The Multiply/Accumulate unit is available as

sink/source capability of the drivers of the I/O

standard. This MAC unit adds powerful DSP

pads are programmable. Refer to Section 12.2 -.

functions to the ST10 architecture, but maintains

full compatibility for existing code. – The Real Time Clock functionality is added.

– The external interrupt sources can be selected

– Flash control interface is now based on

with the EXISEL register.

STMicroelectronics third generation of

stand-alone Flash memories, with an embedded – The reset source is identified by a dedicated

Erase/Program Controller. This completely status bit in the WDTCON register.

Figure 1 : Logic Symbol

V DC1 DC2 V

DD SS

XTAL1

Port 0

XTAL2 16-bit

RSTIN

Port 1

16-bit

RSTOUT

RPD

Port 2

16-bit

V

AREF

V

AGND Port 3

ST10F269 15-bit

NMI

EA

Port 4

8-bit

READY

Port 6

ALE

8-bit

RD

Port 7

WR/WRL

8-bit

Port 5

16-bit Port 8

8-bit

6/184

ST10F269 2 - PIN DATA

2 - PIN DATA

Figure 2 : Pin Configuration (top view)

P6.0/CS0 1

108 P0H.0/AD8

2

P6.1/CS1

107 P0L.7/AD7

3

P6.2/CS2

106 P0L.6/AD6

4

P6.3/CS3

105 P0L.5/AD5

5

P6.4/CS4

104 P0L.4/AD4

6

P6.5/HOLD

103 P0L.3/AD3

7

P6.6/HLDA

102 P0L.2AD2

P6.7/BREQ 8

101 P0L.A/AD1

P8.0/CC16IO 9

100

P0L.0/AD0

P8.1/CC17IO 10

EA

99

P8.2/CC18IO 11

98 ALE

P8.3/CC19IO 12

97 READY

P8.4/CC20IO 13

96 WR/WRL

14

P8.5/CC21IO

95 RD

15

P8.6/CC22IO

94

V

SS

16

P8.7/CC23IO

93

V

DD

17

DC2

92 P4.7A23/CAN2_TxD

18

V

SS

91 P4.6A22/CAN1_TxD

19

P7.0/POUT0

ST10F269

90 P4.5A21/CAN1_RxD

P7.1/POUT1 20

89 P4.4A20/CAN2_RxD

P7.2/POUT2 21

88 P4.3/A19

P7.3/POUT3 22

87 P4.2/A18

P7.4/CC28I0 23

86 P4.1/A17

P7.5/CC29I0 24

85 P4.0/A16

25

P7.6/CC30I0

84 RPD

26

P7.7/CC31I0

V

83

SS

27

P5.0/AN0

82 V

DD

28

P5.1/AN1

81 P3.15/CLKOUT

29

P5.2/AN2

80 P3.13/SCLK

30

P5.3/AN3

79 P3.12/BHE/WRH

P5.4/AN4 31

78 P3.11/RXD0

P5.5/AN5 32

77 P3.10/TXD0

P5.6/AN6 33

76 P3.9/MTSR

P5.7/AN7 34

75 P3.8/MRST

P5.8/AN8 35

74

P3.7/T2IN

P5.9/AN9 36

73 P3.6/T3IN

Table 1 : Pin Description

7/184

V

AREF 37

V 144 V

DD

AGND 38

143 V

P5.10/AN10/T6EUD 39

SS

P5.11/AN11/T5EUD

40 142 NMI

P5.12/AN12/T6IN RSTOUT

41 141

140 RSTIN

P5.13/AN13/T5IN 42

139 V

P5.14/AN14/T4EUD 43

SS

138

P5.15/AN15/T2EUD 44 XTAL1

V

SS 45 137 XTAL2

V

46 V

DD 136

DD

P2.0/CC0IO 47 135 P1H.7/A15/CC27IO

134

P2.1/CC1IO 48 P1H.6/A14/CC26IO

P2.2/CC2IO 49 133 P1H.5/A13/CC25IO

50 132 P1H.4/A12/CC24IO

P2.3/CC3IO

131 P1H.3/A11

P2.4/CC4IO 51

52 130 P1H.2/A10

P2.5/CC5IO

129 P1H.1/A9

P2.6/CC6IO 53

128 P1H.0/A8

P2.7/CC7IO 54

V 127 V

55 SS

SS

DC1

126 V

56

DD

P2.8/CC8IO/EX0IN 57

125 P1L.7/A7

124

P2.9/CC9IO/EX1IN 58 P1L.6/A6

123

P2.10/CC10IOEX2IN 59 P1L.5/A5

P2.11/CC11IOEX3IN 60 122

P1L.4/A4

P2.12/CC12IO/EX4IN 61 121 P1L.3/A3

62 120 P1L.2/A2

P2.13/CC13IO/EX5IN

63 119 P1L.1/A1

P2.14/CC14IO/EX6IN

64 118 P1L.0/A0

P2.15/CC15IO/EX7IN/T7IN

65 117 P0H.7/AD15

P3.0/T0IN

116 P0H.6/AD14

P3.1/T6OUT 66

67 115 P0H.5/AD13

P3.2/CAPIN

114 P0H.4/AD12

P3.3/T3OUT 68

P0H.3/AD11

P3.4/T3EUD 69 113

112 P0H.2/AD10

P3.5/T4IN 70

V P0H.1/AD9

71 111

SS

V 72 V

DD 110

SS

V

109

DD

2 - PIN DATA ST10F269

Symbol Pin Type Function

P6.0 - P6.7 1 - 8 I/O 8-bit bidirectional I/O port, bit-wise programmable for input or output via direction

bit. Programming an I/O pin as input forces the corresponding output driver to high

impedance state. Port 6 outputs can be configured as push-pull or open drain

drivers. The following Port 6 pins have alternate functions:

1OP6.0 CS0 Chip Select 0 Output

... ... ... ... ...

5OP6.4 CS4 Chip Select 4 Output

6IP6.5 HOLD External Master Hold Request Input

7OP6.6 HLDA Hold Acknowledge Output

8 O P6.7 BREQ Bus Request Output

P8.0 - P8.7 9-16 I/O 8-bit bidirectional I/O port, bit-wise programmable for input or output via direction

bit. Programming an I/O pin as input forces the corresponding output driver to high

impedance state. Port 8 outputs can be configured as push-pull or open drain

drivers. The input threshold of Port 8 is selectable (TTL or special).

The following Port 8 pins have alternate functions:

9 I/O P8.0 CC16IO CAPCOM2: CC16 Capture Input / Compare Output

... ... ... ... ...

16 I/O P8.7 CC23IO CAPCOM2: CC23 Capture Input / Compare Output

P7.0 - P7.7 19-26 I/O 8-bit bidirectional I/O port, bit-wise programmable for input or output via direction

bit. Programming an I/O pin as input forces the corresponding output driver to high

impedance state. Port 7 outputs can be configured as push-pull or open drain

drivers. The input threshold of Port 7 is selectable (TTL or special).

The following Port 7 pins have alternate functions:

19 O P7.0 POUT0 PWM Channel 0 Output

... ... ... ... ...

22 O P7.3 POUT3 PWM Channel 3 Output

23 I/O P7.4 CC28IO CAPCOM2: CC28 Capture Input / Compare Output

... ... ... ... ...

26 I/O P7.7 CC31IO CAPCOM2: CC31 Capture Input / Compare Output

P5.0 - P5.9 27-36 I 16-bit input-only port with Schmitt-Trigger characteristics. The pins of Port 5 can be

P5.10 - P5.15 39-44 I the analog input channels (up to 16) for the A/D converter, where P5.x equals ANx

(Analog input channel x), or they are timer inputs:

39 I P5.10 T6EUD GPT2 Timer T6 External Up / Down Control Input

40 I P5.11 T5EUD GPT2 Timer T5 External Up / Down Control Input

41 I P5.12 T6IN GPT2 Timer T6 Count Input

42 I P5.13 T5IN GPT2 Timer T5 Count Input

43 I P5.14 T4EUD GPT1 Timer T4 External Up / Down Control Input

44 I P5.15 T2EUD GPT1 Timer T2 External Up / Down Control Input

8/184

ST10F269 2 - PIN DATA

Symbol Pin Type Function

P2.0 - P2.7 47-54 I/O 16-bit bidirectional I/O port, bit-wise programmable for input or output via direction

P2.8 - P2.15 57-64 bit. Programming an I/O pin as input forces the corresponding output driver to high

impedance state. Port 2 outputs can be configured as push-pull or open drain

drivers. The input threshold of Port 2 is selectable (TTL or special).

The following Port 2 pins have alternate functions:

47 I/O P2.0 CC0IO CAPCOM: CC0 Capture Input / Compare Output

... ... ... ... ...

54 I/O P2.7 CC7IO CAPCOM: CC7 Capture Input / Compare Output

57 I/O P2.8 CC8IO CAPCOM: CC8 Capture Input / Compare Output

I EX0IN Fast External Interrupt 0 Input

... ... ... ... ...

64 I/O P2.15 CC15IO CAPCOM: CC15 Capture Input / Compare Output

I EX7IN Fast External Interrupt 7 Input

I T7IN CAPCOM2 Timer T7 Count Input

P3.0 - P3.5 65-70, I/O 15-bit (P3.14 is missing) bidirectional I/O port, bit-wise programmable for input or

P3.6 - P3.13, 73-80, I/O output via direction bit. Programming an I/O pin as input forces the corresponding

P3.15 81 I/O output driver to high impedance state. Port 3 outputs can be configured as push-pull

or open drain drivers. The input threshold of Port 3 is selectable (TTL or special).

The following Port 3 pins have alternate functions:

65 I P3.0 T0IN CAPCOM Timer T0 Count Input

66 O P3.1 T6OUT GPT2 Timer T6 Toggle Latch Output

67 I P3.2 CAPIN GPT2 Register CAPREL Capture Input

68 O P3.3 T3OUT GPT1 Timer T3 Toggle Latch Output

69 I P3.4 T3EUD GPT1 Timer T3 External Up / Down Control Input

70 I P3.5 T4IN GPT1 Timer T4 Input for Count / Gate / Reload / Capture

73 I P3.6 T3IN GPT1 Timer T3 Count / Gate Input

74 I P3.7 T2IN GPT1 Timer T2 Input for Count / Gate / Reload / Capture

75 I/O P3.8 MRST SSC Master-Receiver / Slave-Transmitter I/O

76 I/O P3.9 MTSR SSC Master-Transmitter / Slave-Receiver O/I

77 O P3.10 TxD0 ASC0 Clock / Data Output (Asynchronous /

Synchronous)

78 I/O P3.11 RxD0 ASC0 Data Input (Asynchronous) or I/O (Synchronous)

79 O P3.12 BHE External Memory High Byte Enable Signal

WRH External Memory High Byte Write Strobe

80 I/O P3.13 SCLK SSC Master Clock Output / Slave Clock Input

81 O P3.15 CLKOUT System Clock Output (=CPU Clock)

9/184

2 - PIN DATA ST10F269

Symbol Pin Type Function

P4.0 –P4.7 85-92 I/O Port 4 is an 8-bit bidirectional I/O port. It is bit-wise programmable for input or output

via direction bit. Programming an I/O pin as input forces the corresponding output

driver to high impedance state. The input threshold is selectable (TTL or special).

Port 4.6 & 4.7 outputs can be configured as push-pull or open drain drivers.

In case of an external bus configuration, Port 4 can be used to output the segment

address lines:

85 O P4.0 A16 Segment Address Line

86 O P4.1 A17 Segment Address Line

87 O P4.2 A18 Segment Address Line

88 O P4.3 A19 Segment Address Line

89 O P4.4 A20 Segment Address Line

I CAN2_RxD CAN2 Receive Data Input

90 O P4.5 A21 Segment Address Line

I CAN1_RxD CAN1 Receive Data Input

91 O P4.6 A22 Segment Address Line

O CAN1_TxD CAN1 Transmit Data Output

92 O P4.7 A23 Most Significant Segment Address Line

O CAN2_TxD CAN2 Transmit Data Output

RD 95 O External Memory Read Strobe. RD is activated for every external instruction or data

read access.

WR/WRL 96 O External Memory Write Strobe. In WR-mode this pin is activated for every external

data write access. In WRL mode this pin is activated for low Byte data write

accesses on a 16-bit bus, and for every data write access on an 8-bit bus. See

WRCFG in the SYSCON register for mode selection.

READY/ 97 I Ready Input. The active level is programmable. When the Ready function is

READY enabled, the selected inactive level at this pin, during an external memory access,

will force the insertion of waitstate cycles until the pin returns to the selected active

level.

ALE 98 O Address Latch Enable Output. In case of use of external addressing or of multi-

plexed mode, this signal is the latch command of the address lines.

EA 99 I External Access Enable pin. A low level applied to this pin during and after Reset

forces the ST10F269 to start the program from the external memory space. A high

level forces the MCU to start in the internal memory space.

10/184

ST10F269 2 - PIN DATA

Symbol Pin Type Function

P0L.0 - P0L.7, 100-107, I/O Two 8-bit bidirectional I/O ports P0L and P0H, bit-wise programmable for input or

P0H.0 108, output via direction bit. Programming an I/O pin as input forces the corresponding

P0H.1 - P0H.7 111-117 output driver to high impedance state.

In case of an external bus configuration, PORT0 serves as the address (A) and as

the address / data (AD) bus in multiplexed bus modes and as the data (D) bus in

demultiplexed bus modes.

Demultiplexed bus modes

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: D0 – D7 D0 - D7

P0H.0 – P0H.7 I/O D8 - D15

Multiplexed bus modes

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: AD0 – AD7 AD0 - AD7

P0H.0 – P0H.7 A8 – A15 AD8 - AD15

P1L.0 - P1L.7 118-125 I/O Two 8-bit bidirectional I/O ports P1L and P1H, bit-wise programmable for input or

P1H.0 - P1H.7 128-135 output via direction bit. Programming an I/O pin as input forces the corresponding

output driver to high impedance state. PORT1 is used as the 16-bit address bus (A)

in demultiplexed bus modes and also after switching from a demultiplexed bus mode

to a multiplexed bus mode.

The following PORT1 pins have alternate functions:

132 I P1H.4 CC24IO CAPCOM2: CC24 Capture Input

133 I P1H.5 CC25IO CAPCOM2: CC25 Capture Input

134 I P1H.6 CC26IO CAPCOM2: CC26 Capture Input

135 I P1H.7 CC27IO CAPCOM2: CC27 Capture Input

XTAL1 138 I XTAL1 Oscillator amplifier and/or external clock input.

XTAL2 137 O XTAL2 Oscillator amplifier circuit output.

To clock the device from an external source, drive XTAL1 while leaving XTAL2

unconnected. Minimum and maximum high / low and rise / fall times specified in the

AC Characteristics must be observed.

RSTIN 140 I Reset Input with Schmitt-Trigger characteristics. A low level at this pin for a specified

duration while the oscillator is running resets the ST10F269. An internal pull-up

resistor permits power-on reset using only a capacitor connected to V . In bidirec-

SS

tional reset mode (enabled by setting bit BDRSTEN in SYSCON register), the

RSTIN line is pulled low for the duration of the internal reset sequence.

RSTOUT 141 O Internal Reset Indication Output. This pin is driven to a low level during hardware,

software or watchdog timer reset. RSTOUT remains low until the EINIT (end of ini-

tialization) instruction is executed.

NMI 142 I Non-Maskable Interrupt Input. A high to low transition at this pin causes the CPU to

vector to the NMI trap routine. If bit PWDCFG = ‘0’ in SYSCON register, when the

PWRDN (power down) instruction is executed, the NMI pin must be low in order to

force the ST10F269 to go into power down mode. If NMI is high and PWDCFG =’0’,

when PWRDN is executed, the part will continue to run in normal mode.

If not used, pin NMI should be pulled high externally.

V 37 - A/D converter reference voltage.

AREF

V 38 - A/D converter reference ground.

AGND

RPD 84 - Timing pin for the return from interruptible powerdown mode and synchronous /

asynchronous reset selection.

11/184

2 - PIN DATA ST10F269

Symbol Pin Type Function

V 46, 72, - Digital Supply Voltage:

DD

82,93, = + 5V during normal operation and idle mode.

109,

126,

136, 144

V 18,45, - Digital Ground.

SS

55,71,

83,94,

110,

127,

139, 143

DC1 56 - 3.3V Decoupling pin (2.7V on TQFP144 devices): a decoupling capacitor of ≥ 330

DC2 17 - nF must be connected between this pin and nearest V pin.

SS

12/184

ST10F269 3 - FUNCTIONAL DESCRIPTION

3 - FUNCTIONAL DESCRIPTION

The architecture of the ST10F269 combines block diagram gives an overview of the different

advantages of both RISC and CISC processors on-chip components and the high bandwidth

and an advanced peripheral subsystem. The internal bus structure of the ST10F269.

Figure 3 : Block Diagram

32 16

2K Byte

128K/256K Byte

16

Internal

Flash Memory CPU-Core and MAC Unit

RAM

Watchdog

16

10K Byte PEC

Oscillator

XRAM

and PLL

P4.5 CAN1_RXD

XTAL1 XTAL2

CAN1

P4.6 CAN1_TXD

Interrupt Controller

16

3.3V Voltage

P4.4 CAN2_RXD

CAN2 Regulator

P4.7 CAN2_TXD

16

16

16

BRG

BRG

8

Port 7

Port 6 Port 5 Port 3 Port 8

8 8

16 15 8

13/184

Port 4 Port 1 Port 0

External Bus

Controller

10-Bit ADC

GPT1

GPT2

ASC usart

SSC

PWM

CAPCOM2

CAPCOM1

Port 2

4 - MEMORY ORGANIZATION ST10F269

4 - MEMORY ORGANIZATION

The memory space of the ST10F269 is configured which are used to control and to monitor the

in a unified memory architecture. Code memory,

function of the different on-chip units.

data memory, registers and I/O ports are

CAN1: Address range 00’EF00h - 00’EFFFh is

organized within the same linear address space of

reserved for the CAN1 Module access. The CAN1

16M Bytes. The entire memory space can be

accessed Byte wise or Word wise. Particular

is enabled by setting XPEN bit 2 of the SYSCON

portions of the on-chip memory have additionally

register and by setting CAN1EN bit 0 of the new

been made directly bit addressable.

XPERCON register. Accesses to the CAN Module

Flash: 128K or 256K Bytes of on-chip Flash use demultiplexed addresses and a 16-bit data

memory. bus (Byte accesses are possible). Two wait states

give an access time of 100ns at 40MHz CPU clock

IRAM: 2K Bytes of on-chip internal RAM

on PQFP144 devices (or 125ns at 32MHz CPU

(dual-port) is provided as a storage for data,

clock on TQFP144 devices). No tri-state wait

system stack, general purpose register banks and

code. A register bank is 16 Wordwide (R0 to R15) states are used.

and / or Bytewide (RL0, RH0, …, RL7, RH7)

CAN2: Address range 00’EE00h - 00’EEFFh is

general purpose registers.

reserved for the CAN2 Module access. The CAN2

XRAM: 10K Bytes of on-chip extension RAM

is enabled by setting XPEN bit 2 of the SYSCON

(single port XRAM) is provided as a storage for

register and by setting CAN2EN bit 1 of the new

data, user stack and code.

XPERCON register. Accesses to the CAN Module

The XRAM is divided into 2 areas, the first 2K

use demultiplexed addresses and a 16-bit data

Bytes named XRAM1 and the second 8K Bytes

bus (Byte accesses are possible). Two wait states

named XRAM2, connected to the internal XBUS

give an access time of 100ns at 40MHz CPU clock

and are accessed like an external memory in

on PQFP144 devices (or 125ns at 32MHz CPU

16-bit demultiplexed bus-mode without wait state

clock on TQFP144 devices). No tri-state wait

or read/write delay (50ns access at 40MHz CPU

states are used.

clock on PQFP144 devices and 62.5ns access at

32MHz CPU clock on TQFP144 devices). Byte

In order to meet the needs of designs where more

and Word accesses are allowed.

memory is required than is provided on chip, up to

The XRAM1 address range is 00’E000h

16M Bytes of external RAM and/or ROM can be

- 00’E7FFh if XPEN (bit 2 of SYSCON register),

connected to the microcontroller.

and XRAM1EN (bit 2 of XPERCON register) are

set. If XRAM1EN or XPEN is cleared, then any

Note If one or the two CAN modules are used, Port

access in the address range 00’E000h - 00’E7FFh

4 cannot be programmed to output all 8

will be directed to external memory interface,

segment address lines. Thus, only 4 segment

using the BUSCONx register corresponding to

address lines can be used, reducing the

address matching ADDRSELx register

external memory space to 5M Bytes (1M Byte

per CS line).

The XRAM2 address range is 00’C000h

- 00’DFFFh if XPEN (bit 2 of SYSCON register),

Visibility of XBUS Peripherals

and XRAM2 (bit 3 of XPERCON register are set).

If bit XRAM2EN or XPEN is cleared, then any

In order to keep the ST10F269 compatible with

access in the address range 00’C000h

the ST10C167 and with the ST10F167, the XBUS

- 00’DFFFh will be directed to external memory

peripherals can be selected to be visible and / or

interface, using the BUSCONx register

accessible on the external address / data bus.

corresponding to address matching ADDRSELx

CAN1EN and CAN2EN bits of XPERCON register

register.

must be set. If these bits are cleared before the

As the XRAM appears like external memory, it

global enabling with XPEN-bit in SYSCON

cannot be used as system stack or as register

banks. The XRAM is not provided for single bit

register, the corresponding address space, port

storage and therefore is not bit addressable.

pins and interrupts are not occupied by the

peripheral, thus the peripheral is not visible and

SFR/ESFR: 1024 Bytes (2 x 512 Bytes) of

address space is reserved for the special function not available. Refer to Chapter : Special Function

register areas. SFRs are Wordwide registers Register Overview on page 125.

14/184

ST10F269 4 - MEMORY ORGANIZATION

Figure 4 : ST10F269 On-chip Memory Mapping

RAM, SFR and X-pheripherals are

mapped into the address space.

14

05’0000

00’FFFF

Block6 = 64K Bytes*

SFR : 512 Bytes

04’0000

10 00’FE00

00’FDFF

Block5 = 64K Bytes*

IRAM : 2K Bytes

0C 03’0000

00’F600

Block4 = 64K Bytes

00’F1FF

02’0000

08

ESFR : 512 Bytes

07

00’F000

Block3 = 32K Bytes Bank 1H

06

00’EFFF

01’8000

CAN1 : 256 Bytes

05

Block2**

Block1** 00’EF00

Bank 1L

Block0**

04

00’EEFF

01’0000

CAN2 : 256 Bytes

03 00’EE00

00’C000

00’EC14

02

Real Time Clock

00’EC00

Block2 = 8K Bytes

00’6000

01

Block1 = 8K Bytes

00’4000

00’E7FF

Bank OL

XRAM1 : 2K Bytes

00 Block0 = 16K Bytes

00’E000

00’0000

00’DFFF

XRAM2 : 8K Bytes

Data Absolute Internal

Page Memory Flash

00’C000

Number Address

Memory

*Reserved area for 128K versions.

** Bank 0L may be remapped from segment 0 to segment 1 (Bank 1L) by setting SYSCON-ROMS1 (before EINIT)

Data Page Number and Absolute Memory Address are hexadecimal values.

15/184

Segment 0 Segment 1 Segment 2 Segment 3 Segment 4

4 - MEMORY ORGANIZATION ST10F269

XPERCON (F024h / 12h) ESFR Reset Value: - - 05h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- --- --- - RTCEN

- -- XRAM2EN XRAM1EN CAN2EN CAN1EN

RW RW RW RW RW

CAN1EN CAN1 Enable Bit

‘0’: Accesses to the on-chip CAN1 XPeripheral and its functions are disabled. P4.5 and P4.6 pins can be

used as general purpose I/Os. Address range 00’EF00h-00’EFFFh is only directed to external memory if

CAN2EN is also ‘0’.

‘1’: The on-chip CAN1 XPeripheral is enabled and can be accessed.

CAN2EN CAN2 Enable Bit

‘0’: Accesses to the on-chip CAN2 XPeripheral and its functions are disabled. P4.4 and P4.7 pins can be

used as general purpose I/Os. Address range 00’EE00h-00’EEFFh is only directed to external memory if

CAN1EN is also ‘0’.

‘1’: The on-chip CAN2 XPeripheral is enabled and can be accessed.

XRAM1EN XRAM1 Enable Bit

‘0’: Accesses to external memory within space 00’E000h to 00’E7FFh. The 2K Bytes of internal XRAM1

are disabled.

’1’: Accesses to the internal 2K Bytes of XRAM1.

XRAM2EN XRAM2 Enable Bit

‘0’: Accesses to the external memory within space 00’C000h to 00’DFFFh. The 8K Bytes of internal

XRAM2 are disabled.

’1’: Accesses to the internal 8K Bytes of XRAM2.

RTCEN RTC Enable Bit

’0’: Accesses to the on-chip Real Time Clock are disabled, external access is performed. Address range

00’EC00h-00’ECFFh is only directed to external memory if CAN1EN and CAN2EN are ’0’ also

’1’: The on-chip Real Time Clock is enabled and can be accessed.

Note: - When both CAN are disabled via XPER- The access to external memory and/or

CON setting, then any access in the XBus is controlled by the bondout chip.

address range 00’EE00h - 00’EFFFh will

- When the Real Time Clock is disabled

be directed to external memory interface,

(RTCEN = 0), the clock oscillator is

using the BUSCONx register correspond-

switch-off if the ST10 enters in

ing to address matching ADDRSELx regis-

power-down mode. Otherwise, when the

ter. P4.4 and P4.7 can be used as General

Real Time Clock is enabled, the bit

Purpose I/O when CAN2 is disabled, and

RTCOFF of the RTCCON register allows

P4.5 and P4.6 can be used as General

to choose the power-down mode of the

Purpose I/O when CAN1 is disabled.

clock oscillator (See Chapter : Real Time

- The default XPER selection after Reset is Clock on page 105).

identical to XBUS configuration of

ST10C167: XCAN1 is enabled, XCAN2 is

disabled, XRAM1 (2K Byte compatible

XRAM) is enabled, XRAM2 (new 8K Byte

XRAM) is disabled.

- Register XPERCON cannot be changed

after the global enabling of XPeripherals,

i.e. after the setting of bit XPEN in the

SYSCON register.

- In EMUlation mode, all the XPERipherals

are enabled (XPERCON bit are all set).

16/184

ST10F269 5 - INTERNAL FLASH MEMORY

5 - INTERNAL FLASH MEMORY

5.1 - Overview Access to data of internal Flash can only be per-

formed with an inner protected program

– 128K or 256K Byte on-chip Flash memory

– Erase Suspend and Resume Modes

– Two possibilities of Flash mapping into the CPU

address space Read and Program another Block during erase

suspend

– Flash memory can be used for code and data

storage – Single Voltage operation, no need of dedicated

supply pin

– 32-bit, zero waitstate read access (50ns cycle

time at f = 40MHz on PQFP144 devices and – Low Power Consumption:

CPU

62.5ns cycle time at f = 32MHz on TQFP144

CPU

45mA max. Read current

devices)

60mA max. Program or Erase current

– Erase-Program Controller (EPC) similar to

M29F400B STM’s stand-alone Flash memory Automatic Stand-by-mode (50 μA maximum)

Word-by-Word Programmable (16 μs typical)

– 1000 Erase-Program Cycles per block, 20 years

of data retention time

Data polling and Toggle Protocol for EPC

o

Status

– Operating temperature: -40 to +125 C / -40 to

o

+125 C Ready/Busy signal connected on XP2INT

interrupt line

5.2 - Operational Overview

Internal Power-On detection circuit

Read Mode

– Memory Erase in blocks

In standard mode (the normal operating mode) One 16K Byte, two 8K Byte, one 32K Byte, one

the Flash appears like an on-chip ROM with the

to three 64K Byte blocks

same timing and functionality. The Flash module

Each block can be erased separately

offers a fast access time, allowing zero waitstate

(1.5 second typical)

access with CPU frequency up to 40MHz on

PQFP144 devices and up to 32MHz on TQFP144 Chip erase (8.5 second typical)

devices. Instruction fetches and data operand

Each block can be separately protected

reads are performed with all addressing modes of

against programming and erasing

the ST10F269 instruction set.

Each protected block can be temporary unpro-

In order to optimize the programming time of the

tected

internal Flash, blocks of 8KBytes, 16KBytes,

When enabled, the read protection prevents 32K Bytes, 64K Bytes can be used. But the size of

access to data in Flash memory using a pro- the blocks does not apply to the whole memory

gram running out of the Flash memory space. space, see details in Table 2.

Table 2 : 128K or 256K Byte Flash Memory Block Organization

Block Addresses (Segment 0) Addresses (Segment 1) Size (byte)

0 00’0000h to 00’3FFFh 01’0000h to 01’3FFFh 16K

1 00’4000h to 00’5FFFh 01’4000h to 01’5FFFh 8K

2 00’6000h to 00’7FFFh 01’6000h to 01’7FFFh 8K

3 01’8000h to 01’FFFFh 01’8000h to 01’FFFFh 32K

4 02’0000h to 02’FFFFh 02’0000h to 02’FFFFh 64K

5* 03’0000h to 03’FFFFh* 03’0000h to 03’FFFFh* 64K*

6* 04’0000h to 04’FFFFh* 04’0000h to 04’FFFFh* 64K*

*Not available on 128K versions (reserved areas).

17/184

5 - INTERNAL FLASH MEMORY ST10F269

Instructions and Commands cycles can then be performed to erase more than

one block in parallel. When a time-out period

All operations besides normal read operations are

elapses (96μs) after the last cycle, the

initiated and controlled by command sequences

Erase-Program Controller (EPC) automatically

written to the Flash Command Interface (CI). The

starts and times the erase pulse and executes the

Command Interface (CI) interprets words written

erase operation. There is no need to program the

to the Flash memory and enables one of the

block to be erased with ‘0000h’ before an erase

following operations:

operation. Termination of operation is indicated in

– Read memory array

the Flash status register. After erase operation,

– Program Word

the Flash memory locations are read as 'FFFFh’

– Block Erase value.

– Chip Erase

Erase Suspend

– Erase Suspend

A block erase operation is typically executed

– Erase Resume

within 1.5 second for a 64K Byte block. Erasure of

– Block Protection a memory block may be suspended, in order to

read data from another block or to program data in

– Block Temporary Unprotection

another block, and then resumed.

– Code Protection

In-System Programming

Commands are composed of several write cycles

at specific addresses of the Flash memory. The

In-system programming is fully supported. No

different write cycles of such command

special programming voltage is required. Because

sequences offer a fail-safe feature to protect

of the automatic execution of erase and

against an inadvertent write.

programming algorithms, write operations are

A command only starts when the Command

reduced to transferring commands and data to the

Interface has decoded the last write cycle of an

Flash and reading the status. Any code that

operation. Until that last write is performed, Flash

programs or erases Flash memory locations (that

memory remains in Read Mode

writes data to the Flash) must be executed from

memory outside the on-chip Flash memory itself

Notes: 1. As it is not possible to perform write

(on-chip RAM or external memory).

operations in the Flash while fetching code

from Flash, the Flash commands must be

A boot mechanism is provided to support

written by instructions executed from

in-system programming. It works using serial link

internal RAM or external memory.

via USART interface and a PC compatible or other

programming host.

2. Command write cycles do not need to

Read/Write Protection

be consecutively received, pauses are

allowed, save for Block Erase command.

The Flash module supports read and write

During this operation all Erase Confirm

protection in a very comfortable and advanced

commands must be sent to complete any

protection functionality. If Read Protection is

block erase operation before time-out

installed, the whole Flash memory is protected

period expires (typically 96μs). Command

against any "external" read access; read

sequencing must be followed exactly. Any

accesses are only possible with instructions

invalid combination of commands will reset

fetched directly from program Flash memory. For

the Command Interface to Read Mode.

update of the Flash memory a temporary disable

of Flash Read Protection is supported.

Status Register

The device also features a block write protection.

This register is used to flag the status of the

Software locking of selectable memory blocks is

memory and the result of an operation. This

provided to protect code and data. This feature

register can be accessed by read cycles during

will disable both program and erase operations in

the Erase-Program Controller (EPC) operation.

the selected block(s) of the memory. Block

Erase Operation

Protection is accomplished by block specific

This Flash memory features a block erase lock-bit which are programmed by executing a four

architecture with a chip erase capability too. Erase cycle command sequence. The locked state of

is accomplished by executing the six cycle erase blocks is indicated by specific flags in the

command sequence. Additional command write according block status registers. A block may only

18/184

ST10F269 5 - INTERNAL FLASH MEMORY

be temporarily unlocked for update (write) In the standard read mode read accesses are

operations. directly controlled by the Flash memory array,

delivering a 32-bit double Word from the

With the two possibilities for write protection -

addressed position. Read accesses are always

whole memory or block specific - a flexible

aligned to double Word boundaries. Thus, both

installation of write protection is supported to

low order address bit A1 and A0 are not used in

protect the Flash memory or parts of it from

the Flash array for read accesses. The high order

unauthorized programming or erase accesses

address bit A17/A16 define the physical 64K Byte

and to provide virus-proof protection for all system

segment being accessed within the Flash array.

code blocks. All write protection also is enabled

during boot operation.

5.3.2 - Command Mode

Power Supply, Reset

The Flash module uses a single power supply for

Every operation besides standard read operations

both read and write functions. Internally

is initiated by commands written to the Flash

generated and regulated voltages are provided for

command register. The addresses used for

the program and erase operations from 5V supply.

command cycles define in conjunction with the

Once a program or erase cycle has been

actual state the specific step within command

completed, the device resets to the standard read

sequences. With the last command of a command

mode. At power-on, the Flash memory has a

sequence, the Erase-Program Controller (EPC)

setup phase of some microseconds (dependent

starts the execution of the command. The EPC

on the power supply ramp-up). During this phase,

status is indicated during command execution by:

Flash can not be read. Thus, if EA pin is high

(execution will start from Flash memory), the CPU

– The Status Register,

will remains in reset state until the Flash can be

accessed. – The Ready/Busy signal.

5.3 - Architectural Description

5.3.3 - Ready/Busy Signal

The Flash module distinguishes two basic

operating modes, the standard read mode and the

The Ready/Busy (R/B) signal is connected to the

command mode. The initial state after power-on

XPER2 interrupt node (XP2IC). When R/B is high,

and after reset is the standard read mode.

the Flash is busy with a Program or Erase

operation and will not accept any additional

5.3.1 - Read Mode

program or erase instruction. When R/B is Low,

The Flash module enters the standard operating

the Flash is ready for any Read/Write or Erase

mode, the read mode:

operation. The R/B will also be low when the

– After Reset command

memory is put in Erase Suspend mode.

– After every completed erase operation

This signal can be polled by reading XP2IC

– After every completed programming operation

register, or can be used to trigger an interrupt

– After every other completed command

when the Flash goes from Busy to Ready.

execution

– Few microseconds after a CPU-reset has

5.3.4 - Flash Status Register

started

– After incorrect address and data values of

The Flash Status register is used to flag the status

command sequences or writing them in an

of the Flash memory and the result of an

improper sequence

operation. This register can be accessed by Read

cycles during the program-Erase Controller

– After incorrect write access to a read protected

operations. The program or erase operation can

Flash memory

be controlled by data polling on bit FSB.7 of

The read mode remains active until the last

Status Register, detection of Toggle on FSB.6 and

command of a command sequence is decoded

FSB.2, or Error on FSB.5 and Erase Time-out on

which starts directly a Flash array operation, such

FSB.3 bit. Any read attempt in Flash during EPC

as:

operation will automatically output these five bits.

– erase one or several blocks

The EPC sets bit FSB.2, FSB.3, FSB.5, FSB.6

– program a word into Flash array

and FSB.7. Other bits are reserved for future use

– protect / temporary unprotect a block. and should be masked.

19/184

5 - INTERNAL FLASH MEMORY ST10F269

Flash Status (see note for address)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- --- -- - - FSB.7 FSB.6 FSB.5 - FSB.3 FSB.2 - -

RR R R R

FSB.7 Flash Status bit 7: Data Polling Bit

Programming Operation: this bit outputs the complement of the bit 7 of the word being

programmed, and after completion, will output the bit 7 of the word programmed.

Erasing Operation: outputs a ‘0’ during erasing, and ‘1’ after erasing completion.

If the block selected for erasure is (are) protected, FSB.7 will be set to ‘0’ for about 100 µs, and

then return to the previous addressed memory data value.

FSB.7 will also flag the Erase Suspend Mode by switching from ‘0’ to ‘1’ at the start of the

Erase Suspend.

During Program operation in Erase Suspend Mode, FSB.7 will have the same behaviour as in

normal Program execution outside the Suspend mode.

FSB.6 Flash Status bit 6: Toggle Bit

Programming or Erasing Operations: successive read operations of Flash Status register will

deliver complementary values. FSB.6 will toggle each time the Flash Status register is read.

The Program operation is completed when two successive reads yield the same value. The

next read will output the bit last programmed, or a ‘1’ after Erase operation

FSB.6 will be set to‘1’ if a read operation is attempted on an Erase Suspended block. In

addition, an Erase Suspend/Resume command will cause FSB.6 to toggle.

FSB.5 Flash Status bit 5: Error Bit

This bit is set to ‘1’ when there is a failure of Program, block or chip erase operations.This bit

will also be set if a user tries to program a bit to ‘1’ to a Flash location that is currently

programmed with ‘0’.

The error bit resets after Read/Reset instruction.

In case of success, the Error bit will be set to ‘0’ during Program or Erase and then will output

the bit last programmed or a ‘1’ after erasing

FSB.3 Flash Status bit 3: Erase Time-out Bit

This bit is cleared by the EPC when the last Block Erase command has been entered to the

Command Interface and it is awaiting the Erase start. When the time-out period is finished,

after 96 µs, FSB.3 returns back to ‘1’.

FSB.2 Flash Status bit 2: Toggle Bit

This toggle bit, together with FSB.6, can be used to determine the chip status during the Erase

Mode or Erase Suspend Mode. It can be used also to identify the block being Erased

Suspended. A Read operation will cause FSB.2 to Toggle during the Erase Mode. If the Flash

is in Erase Suspend Mode, a Read operation from the Erase suspended block or a Program

operation into the Erase suspended block will cause FSB.2 to toggle.

When the Flash is in Program Mode during Erase Suspend, FSB.2 will be read as ‘1’ if address

used is the address of the word being programmed.

After Erase completion with an Error status, FSB.2 will toggle when reading the faulty sector.

Note: The Address of Flash Status Register is the address of the word being programmed when

Programming operation is in progress, or an address within block being erased when Erasing

operation is in progress.

20/184

ST10F269 5 - INTERNAL FLASH MEMORY

5.3.5 - Flash Protection Register

The Flash Protection register is a non-volatile register that contains the protection status. This register

can be read by using the Read Protection Status (RP) command, and programmed by using the dedi-

cated Set Protection command.

Flash Protection Register (PR)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CP - - - - - - - - BP6* BP5* BP4 BP3 BP2 BP1 BP0

*Not avalaible for 128K versions (reserved areas)

BPx Block x Protection Bit (x = 0...6)

‘0’: the Block Protection is enabled for block x. Programming or erasing the block is not

possible, unless a Block Temporary Unprotection command is issued.

1’: the Block Protection is disabled for block x.

Bit is ‘1’ by default, and can be programmed permanently to ‘0’ using the Set Protection

command but then cannot be set to ‘1’ again. It is therefore possible to temporally disable the

Block Protection using the Block Temporary Unprotection instruction.

CP Code Protection Bit

‘0’: the Flash Code Protection is enabled. Read accesses to the Flash for execution not

performed in the Flash itself are not allowed, the returned value will be 009Bh, whatever the

content of the Flash is.

1’: the Flash Code Protection is disabled: read accesses to the Flash from external or internal

RAM are allowed

Bit is ‘1’ by default, and can be programmed permanently to ‘0’ using the Set Protection

command but then cannot be set to ‘1’ again. It is therefore possible to temporally disable the

Code Protection using the Code Temporary Unprotection instruction.

Status is checked by reading the Flash Status bit

FSB.2, FSB.5, FSB.6 and FSB.7 which show the

status of the EPC. FSB.2, FSB.6 and FSB.7

5.3.6 - Instructions Description

determine if programming is on going or has

completed, and FSB.5 allows a check to be made

Twelve instructions dedicated to Flash memory

for any possible error.

accesses are defined as follow:

Block Erase (BE). This instruction uses a

Read/Reset (RD). The Read/Reset instruction

minimum of six command cycles. The erase

consist of one write cycle with data XXF0h. it can

enable command xx80h is written at address

be optionally preceded by two CI enable coded

1554h after the two-cycle CI enable sequence.

cycles (data xxA8h at address 1554h + data

xx54h at address 2AA8h). Any successive read The erase confirm code xx30h must be written at

cycle following a Read/Reset instruction will read

an address related to the block to be erased

the memory array. A Wait cycle of 10µs is

preceded by the execution of a second CI enable

necessary after a Read/Reset command if the sequence. Additional erase confirm codes must

memory was in program or Erase mode. be given to erase more than one block in parallel.

Additional erase confirm commands must be

Program Word (PW). This instruction uses four

written within a defined time-out period. The input

write cycles. After the two Cl enable coded cycles,

of a new Block Erase command will restart the

the Program Word command xxA0h is written at

time-out period.

address 1554h. The following write cycle will latch

the address and data of the word to be When this time-out period has elapsed, the erase

programmed. Memory programming can be done starts. The status of the internal timer can be

only by writing 0's instead of 1's, otherwise an monitored through the level of FSB.3, if FSB.3 is

error occurs. During programming, the Flash ‘0’, the Block Erase command has been given and

21/184

5 - INTERNAL FLASH MEMORY ST10F269

the time-out is running; if FSB.3 is ‘1’, the time-out

has expired and the EPC is erasing the block(s).

22/184

ST10F269 5 - INTERNAL FLASH MEMORY

If the second command given is not an erase after the Erase Suspend Command has been

confirm or if the coded cycles are wrong, the written. The Flash will then go in normal Read

instruction aborts, and the device is reset to Read Mode, and read from blocks not being erased is

Mode. It is not necessary to program the block valid, while read from block being erased will

with 0000h as the EPC will do this automatically output FSB.2 toggling. During a Suspend phase

before the erasing to FFFFh. Read operations the only instructions valid are Erase Resume and

after the EPC has started, output the Flash Status Program Word. A Read / Reset instruction during

Register. Erase suspend will definitely abort the Erase and

result in invalid data in the block being erased.

During the execution of the erase by the EPC, the

Erase Resume (ER). This instruction can be

device accepts only the Erase Suspend and

given when the memory is in Erase Suspend

Read/Reset instructions. Data Polling bit FSB.7

State. Erase can be resumed by writing the

returns ‘0’ while the erasure is in progress, and ‘1’

command xx30h at any address without any

when it has completed. The Toggle bit FSB.2 and

Cl-enable sequence.

FSB.6 toggle during the erase operation. They

stop when erase is completed. After completion,

Program during Erase Suspend. The Program

the Error bit FSB.5 returns ‘1’ if there has been an

Word instruction during Erase Suspend is allowed

erase failure because erasure has not completed

only on blocks that are not Erase-suspended. This

even after the maximum number of erase cycles

instruction is the same than the Program Word

have been executed by the EPC, in this case, it

instruction.

will be necessary to input a Read/Reset to the

Set Protection (SP). This instruction can be used

Command Interface in order to reset the EPC.

to enable both Block Protection (to protect each

Chip Erase (CE). This instruction uses six write

block independently from accidental Erasing-Pro-

cycles. The Erase Enable command xx80h, must

gramming Operation) and Code Protection (to

be written at address 1554h after CI-Enable

avoid code dump). The Set Protection Command

cycles. The Chip Erase command xx10h must be

must be given after a special CI-Protection Enable

given on the sixth cycle after a second CI-Enable

cycles (see instruction table). The following Write

sequence. An error in command sequence will

cycle, will program the Protection Register. To pro-

reset the CI to Read mode. It is NOT necessary to

tect the block x (x = 0 to 6), the data bit x must be

program the block with 0000h as the EPC will do

at ‘0’. To protect the code, bit 15 of the data must

this automatically before the erasing to FFFFh.

be ‘0’. Enabling Block or Code Protection is per-

Read operations after the EPC has started output

manent and can be cleared only by STM. Block

the Flash Status Register. During the execution of

Temporary Unprotection and Code Temporary

the erase by the EPC, Data Polling bit FSB.7

Unprotection instructions are available to allow the

returns ‘0’ while the erasure is in progress, and ‘1’

customer to update the code.

when it has completed. The FSB.2 and FSB.6 bit

Notes:1. The new value programmed in

toggle during the erase operation. They stop when

protection register will only become active

erase is finished. The FSB.5 error bit returns "1" in

after a reset.

case of failure of the erase operation. The error

2. Bit that are already at ’0’ in protection

flag is set after the maximum number of erase

register must be confirmed at ’0’ also in

cycles have been executed by the EPC. In this

data latched during the 4th cycle of set

case, it will be necessary to input a Read/Reset to

protection command, otherwise an error

the Command Interface in order to reset the EPC.

may occur.

Erase Suspend (ES). This instruction can be

Read Protection Status (RP). This instruction is

used to suspend a Block Erase operation by

used to read the Block Protection status and the

giving the command xxB0h without any specific

Code Protection status. To read the protection

address. No CI-Enable cycles is required. Erase

register (see Table 3), the CI-Protection Enable

Suspend operation allows reading of data from

cycles must be executed followed by the

another block and/or the programming in another

command xx90h at address x2A54h. The

block while erase is in progress. If this command

following Read Cycles at any odd word address

is given during the time-out period, it will terminate

will output the Block Protection Status. The Read/

the time-out period in addition to erase Suspend.

Reset command xxF0h must be written to reset

The Toggle bit FSB.6, when monitored at an

the protection interface.

address that belongs to the block being erased,

stops toggling when Erase Suspend Command is Note: After a modification of protection register

effective, It happens between 0.1μs and 15μs (using Set Protection command), the Read

23/184

5 - INTERNAL FLASH MEMORY ST10F269

Protection Status will return the new PR

value only after a reset.

Block Temporary Unprotection (BTU). This Instruction can be used to temporary unprotect all the

blocks from Program / Erase protection. The Unprotection is disabled after a Reset cycle. The Block

Temporary Unprotection command xxC1h must be given to enable Block Temporary Unprotection. The

Command must be preceded by the CI-Protection Enable cycles and followed by the Read/Reset

command xxF0h.

Set Code Protection (SCP). This kind of protection allows the customer to protect the proprietary code

written in Flash. If installed and active, Flash Code Protection prevents data operand accesses and

program branches into the on-chip Flash area from any location outside the Flash memory itself. Data

operand accesses and branches to Flash locations are only and exclusively allowed for instructions

executed from the Flash memory itself. Every read or jump to Flash performed from another memory (like

internal RAM, external memory) while Code Protection is enabled, will give the opcode 009Bh related to

TRAP #00 illegal instruction. The CI-Protection Enable cycles must be sent to set the Code Protection. By

writing data 7FFFh at any odd word address, the Code Protected status is stored in the Flash Protection

Register (PR). Protection is permanent and cannot be cleared by the user. It is possible to temporarily

disable the Code Protection using Code Temporary Unprotection instruction.

Note: Bits that are already at ’0’ in protection register must be confirmed at ’0’ also in data latched during

the 4th cycle of set protection command, otherwise an error may occur.

Code Temporary Unprotection (CTU). This instruction must be used to temporary disable Code

Protection. This instruction is effective only if executed from Flash memory space. To restore the

protection status, without using a reset, it is necessary to use a Code Temporary Protection instruction.

System reset will reset also the Code Temporary Unprotected status. The Code Temporary Unprotection

command consists of the following write cycle:

MOV MEM, Rn ; This instruction MUST be executed from Flash memory space

Where MEM is an absolute address inside memory space, Rn is a register loaded with data 0FFFFh.

Code Temporary Protection (CTP). This instruction allows to restore Code Protection. This operation is

effective only if executed from Flash memory and is necessary to restore the protection status after the