ROSS 2781A4007

Datasheet

Extracted Text

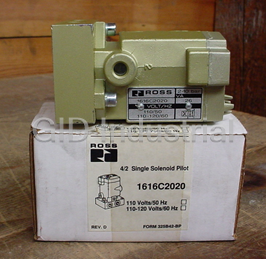

® L-O-X (Lock Out & eXhaust) Valves ® ROSS L-O-X valves are energy isolation valves and are � �� �� � generally used as the first valve in a line supplying com- pressed air to equipment. Air can be shut off by pushing the 2 ® 12 10 red L-O-X handle inward; downstream air is simultaneously Y3 ® exhausted through the L-O-X exhaust port. OSHA compli- ance requires that the valve be padlocked in this position to 2 1 3 prevent handle from being pulled out inadvertently during MANUAL maintenance. 3 1 � ® Piloted L-O-X valves allow the flow of air to be controlled ® remotely as long as the L-O-X control is open. See ROSS ® Bulletin 372D for more information about L-O-X valves. SOLENOID PILOT Port Size Valve Model Avg. C Dimensions inches (mm) Weight v Valve Type* In-Out Exh. Number* In-Out Out-Exh. A B C lb. (kg) MANUAL 3/8 3/4 1523C3002 6.0 8.0 6.3 (159) 8.8 (225) 2.0 (51) 1.5 (0.7) 1/2 3/4 1523C4002 7.1 8.3 6.3 (159) 8.8 (225) 2.0 (51) 1.5 (0.7) 3/4 3/4 1523C5012 8.6 9.5 6.3 (159) 8.8 (225) 2.0 (51) 1.5 (0.7) B 3/4 1-1/4 1523C5002 13 12 7.6 (194)10.6 (270) 2.3 (57) 2.5 (1.1) C 1 1-1/4 1523C6002 13 14 7.6 (194)10.6 (270) 2.3 (57) 2.5 (1.1) 1-1/4 1-1/4 1523C7012 20 14 7.6 (194)10.6 (270) 2.3 (57) 2.5 (1.1) MANUAL PILOT 1 1-1/2 2783A6006 23 34 7.4 (187) 8.6 (218) 6.4 (162) 7.0 (3.2) A 1-1/4 1-1/2 2783A7006 30 32 7.4 (187) 8.6 (218) 6.4 (162) 7.0 (3.2) 1-1/2 1-1/2 2783A8016 30 31 7.4 (187) 8.6 (218) 6.4 (162) 7.0 (3.2) 1-1/2 2-1/2 2783A8006 68 70 8.4 (213)10.2 (259)6.6 (162) 15.3 (6.9) 2 2-1/2 2783A9006 70 70 8.4 (213)10.2 (259)6.6 (162) 15.3 (6.9) 2-1/2 2-1/2 2783A9016 70 71 8.4 (213)10.2 (259)6.6 (162) 15.3 (6.9) C B 1/4 1/2 2773A2072 2.5 3.1 7.1 (181) 8.4 (212) 6.5 (165) 3.5 (1.6) 3/8 1/2 2773A3072 3.6 5.3 7.1 (181) 8.4 (212) 6.5 (165) 3.5 (1.6) A 1/2 1/2 2773A4082 3.3 5.3 7.1 (181) 8.4 (212) 6.5 (165) 3.5 (1.6) 1/2 1 2773A4072 6.3 9.2 7.1 (181) 9.0 (228) 6.9 (175) 4.3 (1.9) 3/4 1 2773A5072 7.7 11 7.1 (181) 9.0 (228) 6.9 (175) 4.3 (1.9) SOLENOID PILOT 1 1 2773A6082 8.0 12 7.1 (181) 9.0 (228) 6.9 (175) 4.3 (1.9) 1 1-1/2 2773A6072 23 34 8.1 (206)11.8 (299)6.9 (175) 8.0 (3.6) 1-1/4 1-1/2 2773A7072 30 32 8.1 (206)11.8 (299)6.9 (175) 8.0 (3.6) 1-1/2 1-1/2 2773A8082 30 31 8.1 (206)11.8 (299)6.9 (175) 8.0 (3.6) 1-1/2 2-1/2 2773A8072 68 70 9.3 (235)13.8 (352)7.3 (184) 17.5 (7.9) � 2 2-1/2 2773A9072 70 70 9.3 (235)13.8 (352)7.3 (184) 17.5 (7.9) 2-1/2 2-1/2 2773A9082 70 71 9.3 (235)13.8 (352)7.3 (184) 17.5 (7.9) � ® * ROSS’ L-O-X products come standard with a gold body and red handle. They can also be ordered with a yellow � body. For NPT thread models with yellow bodies, prefix the number with a “Y” (Y1523C3002). For G thread models with yellow bodies, substitute the center letter with an “X” (D1523X3002). ® L-O-X Sensing Port ® ® ® ® L-O-X Sensing Port - Series 15 L-O-X and L-O-X /EEZ-ON valves are now provided with 1/8 NPT sensing ports, enabling installation of a pressure sensing device such as the Pop-Up Indicator or Pressure Switch shown below. Standards suggest that machine design should include a method for verifying the release of energy after lock-out. The ROSS 988H30 Pop-Up Indicator is constructed for the industrial environment with a brass body and 1/8” NPT connection. It offers 360° visibility and a redundant verification feature. By pushing on the red plunger, the operator can “feel” the presence of pressure and verify that the indicator is performing its sensing function. The ROSS 586A86 Pressure Switch offers an electronic pressure sensing option that can be integrated into a safety monitoring system, which confirms energy isolation throughout the circuit. STANDARD SPECIFICATIONS: Inlet Pressure: Port sizes 3/8 to 1-1/2: 15 to 150 psig (1 to 10 ® Ambient Temperature: Solenoid Valves: 40° to 120°F bar) and 15 to 300 psig on Manual L-O-X (1 to 20 bar). Port sizes (4° to 50°C). 1-1/2 to 2-1/2: 30 to 150 psig (2 to 10 bar). Manual Valves: 40° to 175°F (4° to 80°C). Threads: NPT standard. Prefix the model number with the letter Power Consumption: 87 VA holding on 50 or 60 Hz; 14 “D” for parallel G threads, e.g. D1523C3002. watts on DC. NOTE: Per specifications and regulations, these products are Media Temperature: 40° to 175°F (4° to 80°C). defined as energy isolation devices, NOT AS EMERGENCY Flow Media: Filtered air. 5 micron recommended. STOP DEVICES. � � � � � � � � � � � � ® � 66 ROSS CONTROLS ® EEZ-ON Valves ® 2/2 EEZ-ON Valves Port Valve Model Average Dimensions inches (mm) Weight Size Numbers C AB C lb. (kg) v 1/4 2781A2007 2.3 3.8 (97) 3.8 (97) 3.0 (77) 1.5 (0.7) 3/8 2781A3007 3.8 3.8 (97) 3.8 (97) 3.0 (77) 1.5 (0.7) 2 1/2 2781A4017 4.0 3.8 (97) 3.8 (97) 3.0 (77) 1.5 (0.7) B C 1/2 2781A4007 7.7 4.6 (117) 4.5 (114) 3.0 (77) 2.3 (1.0) 3/4 2781A5007 9.0 4.6 (117) 4.5 (114) 3.0 (77) 2.3 (1.0) 1 1 2781A6017 9.0 4.6 (117) 4.5 (114) 3.0 (77) 2.3 (1.0) A 1 2781A6007 24 6.6 (168) 7.6 (192) 4.1 (103) 6.0 (2.7) 1-1/4 2781A7007 29 6.6 (168) 7.6 (192) 4.1 (103) 6.0 (2.7) 1-1/2 2781A8017 29 6.6 (168) 7.6 (192) 4.1 (103) 6.0 (2.7) ® An EEZ-ON valve is used in an air supply line to provide a gradual buildup of downstream air pressure. This permits cylinders or other work elements to move slowly into their normal working positions before full line pressure is applied. The time required to reach full line pressure is adjustable. ® 3 3/2 EEZ-ON Valves Solenoid Pilot Models 2 ® The 3/2 EEZ-ON valve provides the same gradual ® pressure buildup as the 2/2 EEZ-ON valves described 1 above. In addition, the 3/2 valve has an exhaust port so Y3 that downstream air is exhausted when the valve is de- energized. At the same time, supply air is positively cut off so that a separate cutoff valve is not required. ® NOTE: The 3/2 EEZ-ON valve is also available with a � � ® ® ® L-O-X adapter so that both L-O-X and EEZ-ON func- tions are consolidated in a single valve. See ROSS � Bulletin 372D for more information. � � � Port Size Valve Model Numbers Average C Dimensions inches (mm) Weight V In-Out Exhaust Solenoid Pilot Remote Air Pilot 1 to 2 2 to 3 A B C D lb. (kg) 1/4 1/2 2773B2037 2783B2037 2.5 3.1 4.1 (104) 8.8 (224) 3.1 (79) 5.7 (146) 4.5 (2.0) 3/8 1/2 2773B3037 2783B3037 3.6 5.3 4.1 (104) 8.8 (224) 3.1 (79) 5.7 (146) 4.5 (2.0) 1/2 1/2 2773B4047 2783B4047 3.3 5.3 4.1 (104) 8.8 (224) 3.1 (79) 5.7 (146) 4.5 (2.0) 1/2 1 2773B4037 2783B4037 6.3 9.2 4.9 (124) 9.6 (243) 3.6 (92) 7.1 (180) 5.0 (2.3) 3/4 1 2773B5037 2783B5037 7.7 11 4.9 (124) 9.6 (243) 3.6 (92) 7.1 (180) 5.0 (2.3) 1 1 2773B6047 2783B6047 8.0 12 4.9 (124) 9.6 (243) 3.6 (92) 7.1 (180) 5.0 (2.3) Power Consumption: 87 VA holding on 50 or 60 Hz; 14 IMPORTANT NOTE watts on DC. Please read carefully and thoroughly Flow Media: Filtered air. 5 micron recommended. all of the CAUTIONS on page 89. Inlet Pressure: 2/2 models: 30 to 150 psig (2 to 10 bar). STANDARD SPECIFICATIONS 3/2 models: 15 to 150 psig (1 to 10 bar). Ambient/Media Temperature: 40° to 175°F (4° to 80°C). � � � � � � � � � � � � � www.rosscontrols.com 67 ® ® Combination L-O-X /EEZ-ON Valves ® ® Combines L-O-X Shut-off with EEZ-ON Gradual Starts VALVE OPERATION ® ® The L-O-X /EEZ-ON valve combines shut- VALVE CLOSED off certainty with gradual pressurization upon With a short push of the handle inward, the flow start-up. Special labels and adjustment ® screw indicates EEZ-ON function. of supply is blocked and downstream air is ex- hausted via the exhaust port at the bottom of the ® valve. It is required by OSHA that the L-O-X / 2 1 ® EEZ-ON valve be padlocked in this position to prevent the handle from being pulled outward ® ® inadvertently when potential for human injury The ROSS L-O-X /EEZ-ON valve is the newest addition to ROSS’ 3 renowned family of safety-related products. Combining two func- exists or servicing machinery. tions critical to safety concerns in any application, the ROSS L-O- ® ® X /EEZ-ON valve provides the shutdown and the gradual start-up (or, “soft start”) capabilities today’s systems require. In addition, ® EEZ-ON VALVE FUNCTION ® ® because the L-O-X /EEZ-ON valve is two units in one, you elimi- With the handle pulled out, the adjustable needle nate the need for multiple components. And that means easier 2 1 valve (accessed through top of handle) setting installation and less cost. determines the rate of pressure buildup. The new valve permits the gradual increase of downstream pres- 3 sure in the pneumatic circuit that has just been actuated. The same unit also features a shut-off and lockout of system air to limit inadvertent actuation. For years, ROSS products have been the VALVE OPEN industry benchmark in safety-related pneumatic controls, and the After the handle is pulled out and pressure down- ® ® /EEZ-ON valve. The tradition continues with the new L-O-X stream has gradually increased, the valve auto- exhaust port is threaded for the installation of a silencer or a line for matically changes to a fully open state, allowing 21 remote exhausting. Two mounting holes are provided to simplify full flow from inlet to downstream. See “Toggle ® ® the installation of the L-O-X /EEZ-ON valve. Open Pressure” under standard specifications. 2 3 B C 12 10 1 3 A VALVE MODEL NUMBERS & OVERALL DIMENSIONS ® Port Size Valve Model Average C Dimensions inches (mm) EEZ-ON Weight V In-Out Exhaust Numbers* 1 to 2 2 to 3 A B C Valve Cv** lb. (kg) 3/8 3/4 1523A3102 6.0 8.0 6.4 (163) 8.8 (224) 2.0 (51) 0.6 1.5 (.7) 1/2 3/4 1523A4102 7.1 8.3 6.4 (163) 8.8 (224) 2.0 (51) 0.6 1.5 (.7) VALVE MODEL NUMBERS and OVERALL DIMENSIONS 3/4 3/4 1523A5112 8.0 9.5 6.4 (163) 8.8 (224) 2.0 (51) 0.6 1.5 (.7) 3/4 1-1/4 1523A5102 12.0 10.9 7.7 (196) 10.8 (274) 2.3 (58) 3.0 3.3 (1.5) 1 1-1/4 1523A6102 13.7 12.0 7.7 (196) 10.8 (274) 2.3 (58) 3.0 3.2 (1.5) 1-1/4 1-1/4 1523A7112 16.2 12.8 7.7 (196) 10.8 (274) 2.3 (58) 3.0 3.2 (1.5) ® ® *ROSS L-O-X /EEZ-ON products come standard with gold body and blue handle. These products can also be ordered with yellow-colored body. For NPT thread models with yellow bodies, prefix the number with a “Y” (Y1523C3102). For G thread models with yellow bodies, substitute the center letter with an “X” (D1523X3102). **C from port 1 to port 2 during pressure buildup (before valve opens fully). V ® L-O-X Sensing Port ® ® ® ® L-O-X Sensing Port - Series 15 L-O-X and L-O-X /EEZ-ON valves are now provided with 1/8 NPT sensing ports, enabling installation of a pressure sensing device such as the Pop-Up Indicator or Pressure Switch shown below. Standards suggest that machine design should include a method for verifying the release of energy after lock-out. The ROSS 988H30 Pop-Up Indicator is constructed for the industrial environment with a brass body and 1/8” NPT connection. It offers 360° visibility and a redundant verification feature. By pushing on the red plunger, the operator can “feel” the presenSingle Point Lockout The ROSS 586A86 Pressure Switch offers an electronic pressure sensing option that can be integrated into a safety monitoring system, which confirms energy isolation throughout the circuit. STANDARD SPECIFICATIONS Port Threads: NPT standard. Prefix the model number with o o Ambient/Media Temperature: 40 to 175 F (4 to 80 C). the letter “D” for parallel G threads, e.g. D1523A3102. Flow Media: Filtered air. 5 micron filter recommended. NOTE: Per specifications and regulations, these products are Inlet Pressure: 30 to 150 psig (2 to 10 bar). Toggle Open defined as energy isolation devices, NOT AS EMERGENCY Pressure = Inlet - 25 psig. If different toggle pressure is STOP DEVICES. needed, contact ROSS Technical Services. � � � � � � � � � � � � ® � 68 ROSS CONTROLS ® Right-Angle EEZ-ON Valves ® EEZ-ON Valves ® EEZ-ON Valves are used to gradually apply air pressure downstream when supply is initially applied. Select the model you need to operate with supply pressure at either port 1 or port 2. Right angle design with banjo for easy positioning of pipe or tubing. Models with Threaded Banjo Dimensions Valve Model Numbers Tightening Port Size inches (mm) Torque Max. Primary Pressure Average C B v Port 1* Port 2** Ft-lb (Nm) At Port 1 At Port 2 A B A G1/8 G1/8 D1969A1010 D1969A1011 0.7 0.5 (13) 2.3 (57) 7.38 (10) G1/4 G1/4 D1969A2010 D1969A2011 1.1 0.7 (17) 2.4 (61) 8.85 (12) Slot Port 2 Adjustment G3/8 G3/8 D1969A3010 D1969A3011 1.9 0.9 (22) 2.7 (67) 14.75 (20) G1/2 G1/2 D1969A4010 D1969A4011 2.2 1.1 (27) 2.9 (72) 22.13 (30) Port 1 1/8 1/8 1969A1010 1969A1011 0.7 0.5 (13) 2.3 (57) 11.06 (15) Threaded Banjo 1/4 1/4 1969A2010 1969A2011 1.1 0.7 (17) 2.5 (63) 14.75 (20) 3/8 3/8 1969A3010 1969A3011 1.9 0.9 (22) 2.8 (69) 22.13 (30) 1/2 1/2 1969A4010 1969A4011 2.2 1.1 (27) 2.9 (74) 29.50 (40) * Threads in port 1 are female. ** Port 2 threads are male. Models with Push-to-Connect Fitting Valve Model Numbers Tightening Dimensions Port Size B inches (mm) Torque Max. Average C Primary Pressure v # Port 1** Port 2 Ft-lb (Nm) At Port 1 At Port 2 A B A 4.0 D1969A1020 D1969A1021 Slot 6.0 G1/8 D1969A1030 D1969A1031 0.5 0.5 (13) 2.3 (57) 7.38 (10) Port 2 Adjustment 8.0 D1969A1040 D1969A1041 6.0 D1969A2020 D1969A2021 Port 1 8.0 G1/4 D1969A2030 D1969A2031 0.6 0.7 (17) 2.4 (61) 8.85 (12) 10.0 D1969A2040 D1969A2041 Push-to-Connect 8.0 D1969A3020 D1969A3021 Fitting G3/8 1.5 0.9 (22) 2.7 (67) 14.75 (20) 10.0 D1969A3030 D1969A3031 5/32” 1969A1020 1969A1021 1/8 0.5 0.5 (13) 2.3 (57) 11.06 (15) 1/4” 1969A1030 1969A1031 1/4” 1969A2020 1969A2021 1/4 0.6 0.7 (17) 2.5 (63) 14.75 (20) 3/8” 1969A2030 1969A2031 3/8” 3/8 1969A3020 1969A3021 1.5 0.9 (22) 2.8 (69) 22.13 (30) # Port 1 tubing size in mm ( ) or inches (”). ** Port 2 threads are male. Primary Pressure Primary Pressure at port 2 at port 1 2 2 1 1 STANDARD SPECIFICATIONS: IMPORTANT NOTE Ambient/Media Temperature: 15° to 160°F (-10° to 70°C). Please read carefully and thoroughly Flow Media: Filtered air. 5 micron recommended. all of the CAUTIONS on page 89. Operating Pressure: 45 to 150 psig (3 to 10 bar). � � � � � � � � � � � � � www.rosscontrols.com 69

Frequently asked questions

What makes Elite.Parts unique?

What kind of warranty will the 2781A4007 have?

Which carriers does Elite.Parts work with?

Will Elite.Parts sell to me even though I live outside the USA?

I have a preferred payment method. Will Elite.Parts accept it?

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods