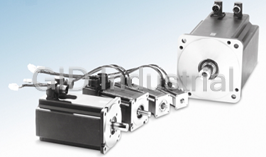

PACIFIC SCIENTIFIC Servo Motor

Datasheet

Extracted Text