ALLEN BRADLEY 9324-RLD300NXENE

Description

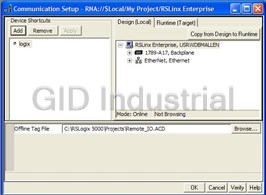

Allen Bradley's 9324-RLD300NXENE Programming Software is most certainly standard and is the relay ladder logic). The RSNetWorx for ControlNet and DeviceNet software, The nice personal computer: IBM-compatible Pentium 90 MHz or greater, the software requirements: Microsoft's Windows NT version 4.0 with Service Pack 4 and the RSLinx software must be installed. RAM: 32Mbytes of RAM minimum and 64 Mbytes of RAM is recommended for sure. The hard disk space: 40Mbytes of free hard disk space or more based on application requirements. Awesome video requirements: 16-color VGA graphics adapter, 640 x 480 or greater resolution, and 256-color 800 x 600 minimum for optimal resolution.

Part Number

9324-RLD300NXENE

Price

Request Quote

Manufacturer

ALLEN BRADLEY

Lead Time

Request Quote

Category

SOFTWARE

Datasheet

Extracted Text